-

Home

-

Products and Solutions

-

Keyto Global

-

News Center

-

Service Support

-

About Us

-

Contact Us

-

语言

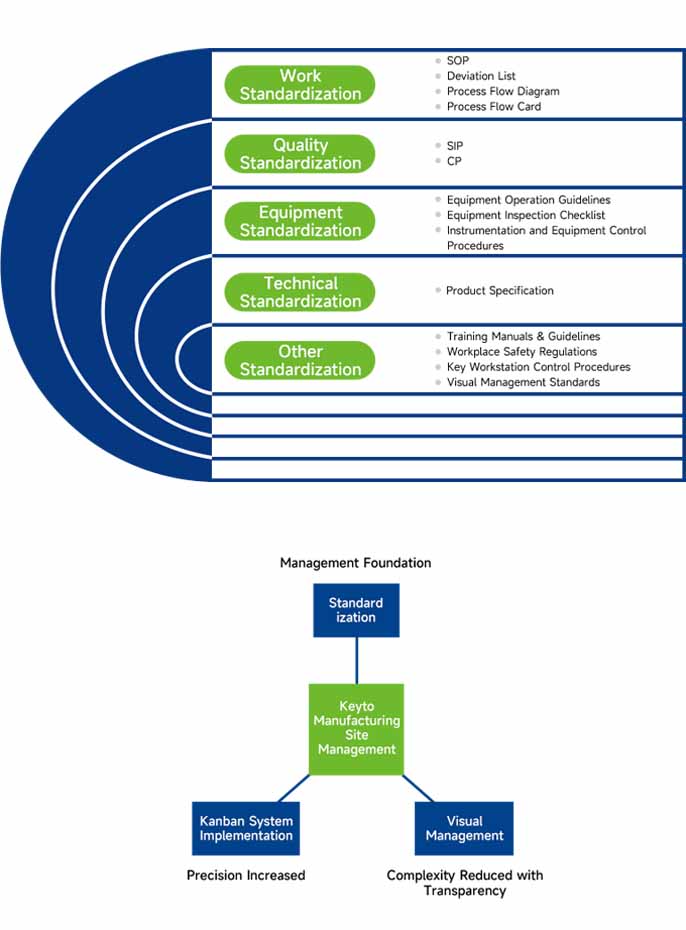

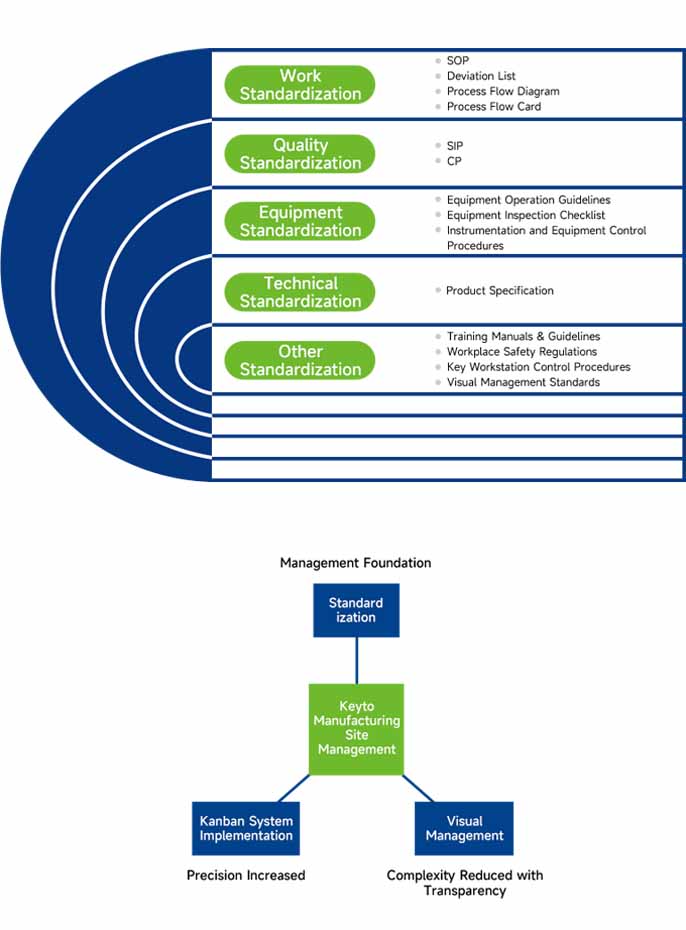

It is mainly supported by the three pillars of standardization/visualization/Kanbanization; standardization is the management foundation of benchmarking, Kanbanization increases the precision, and visualization reduces the difficulty. Standardization: It is mainly embodied in the standardization of operation, quality, equipment, technology and other standardization. Visualization: To create a workplace that is “clear at a glance”, through visual tools such as signboards, logos, objects, light symbols, charts, etc., to define the direction, location, distance, trend, and discrepancy of people, things, and objects, and to carry out on-site management and improvement activities. Kanbanization: Kanban management is an important part of first-class on-site management. Through various types of kanban boards, we can show the management situation to all people, improve transparency, create an internal management atmosphere, enhance customer satisfaction, reduce management costs, and reduce management risks.

Product Line Configurations

PE

IPQC

Configuration of each product line

Production Team Leader

ME Technician

Material man

Complete workshop manpower allocation

IE Engineer

ME Engineer

QE Engineer

Fixture Engineer

Data analyzer