-

Home

-

Products and Solutions

-

Keyto Global

-

News Center

-

Service Support

-

About Us

-

Contact Us

-

语言

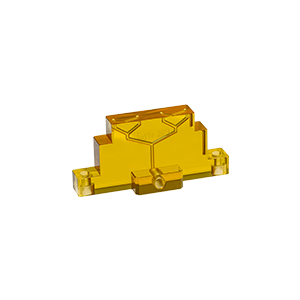

Keyto PEI Diffusion Bonded Manifold | Production-Oriented Custom

Integration-ready manifold base for building higher-level fluidic assemblies.

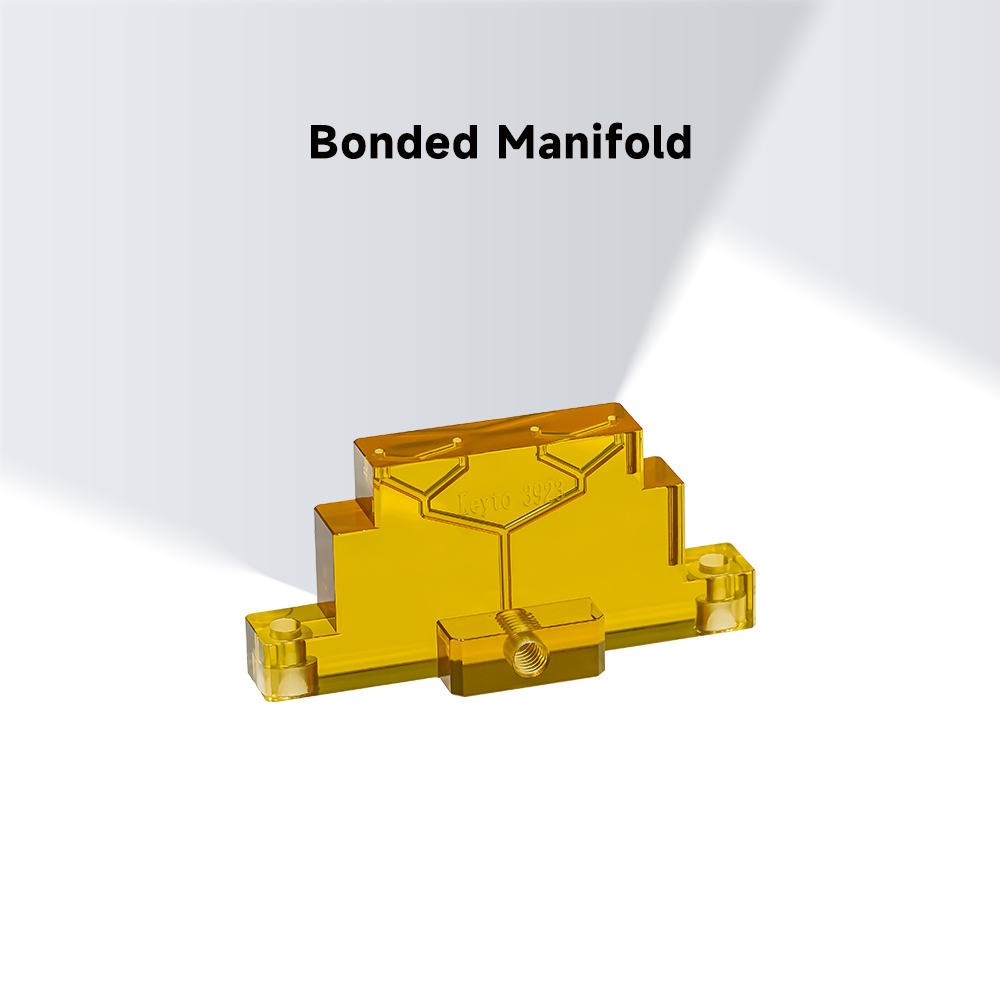

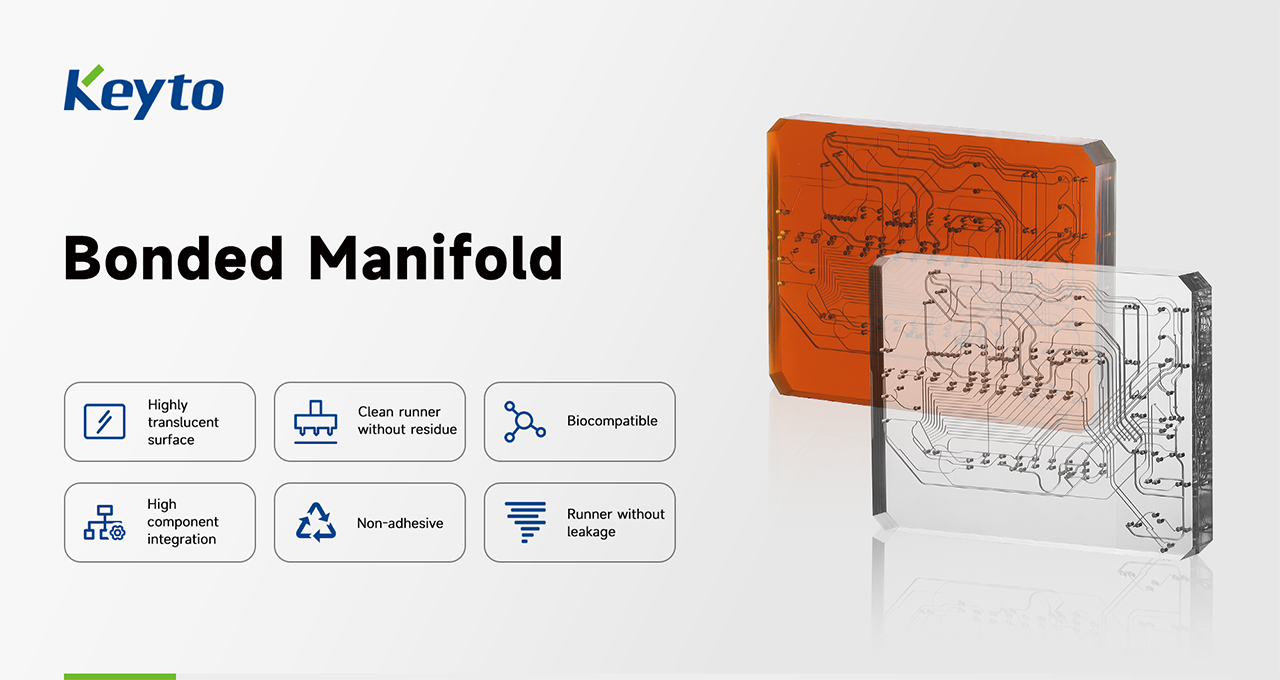

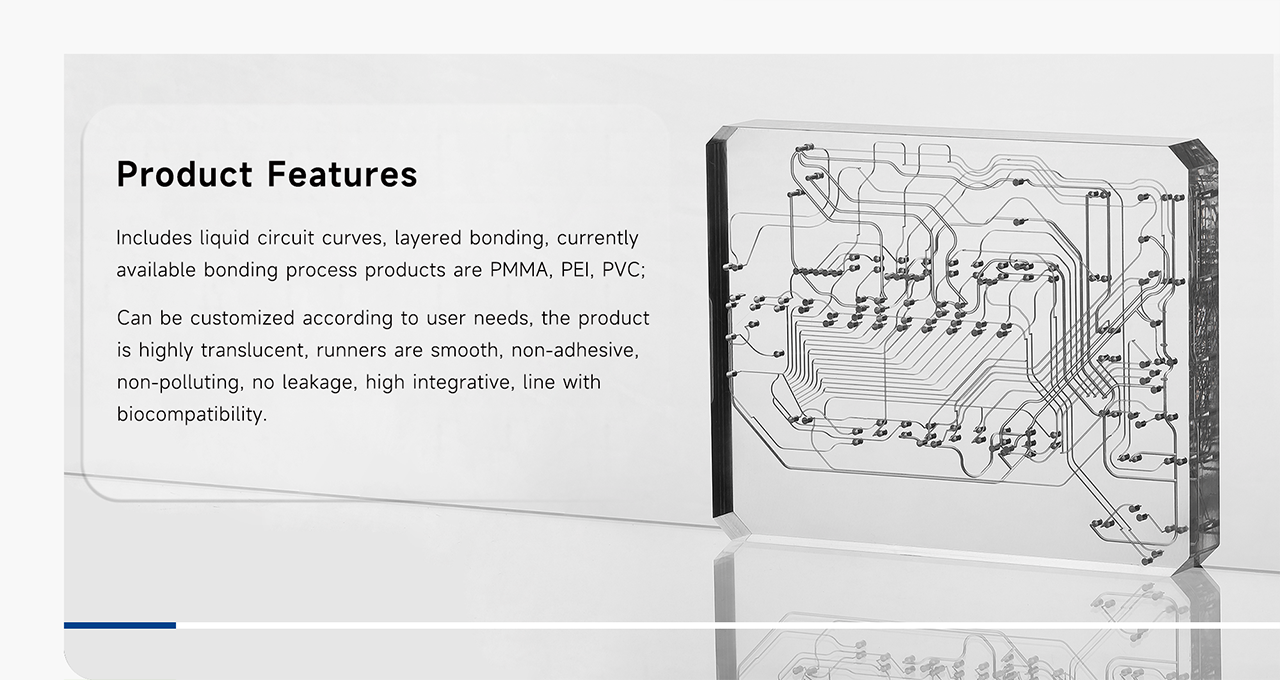

The Keyto PEI-6 diffusion bonded manifold is positioned as an integration-ready fluidic base, enabling faster system build-up and cleaner assembly architecture. Multi-layer diffusion bonding creates sealed, compact routing that can serve as a platform for ports, interfaces, and system-level integration. It supports up to five layers, offers configurable channel geometries (square/round/D-shaped), and can achieve minimum channel features down to 0.5 mm with ±0.01 mm tolerance (design dependent). PEI-6 is a practical choice when you want to reduce tubing complexity, improve maintainability, and prepare the design for future assembly-level integration.

Feature Bullets

- Built as a manifold “base” to streamline system integration planning

- Up to 5 bonded layers for compact, sealed multi-level routing

- 0.5 mm minimum channel feature; ±0.01 mm channel tolerance (design dependent)

- Channel geometry options for performance and layout flexibility

- Helps reduce tubing, fittings, and potential failure points

- Custom ports and interfaces for integration with valves, pumps, or connectors

FAQ

Q1: Can PEI-6 be used in a manifold assembly concept?

A: Yes. It can be designed to support interfaces and mounting features for integration with other fluidic components.

Q2: Do you support multiple materials besides PEI?

A: Yes. Depending on application, PMMA, PEI, COP, PC, PP and other plastics can be considered.

Q3: What is the typical starting point for customization?

A: CAD drawings plus key constraints: footprint, port count, flow targets, media, temperature, and pressure requirements.

Q4: Can you help reduce leak risks?

A: Yes. Consolidating routing into a bonded manifold reduces external connections and can lower the overall leak risk profile.

language

language