-

Home

-

Products and Solutions

-

Keyto Global

-

News Center

-

Service Support

-

About Us

-

Contact Us

-

语言

Feature Bullets

-

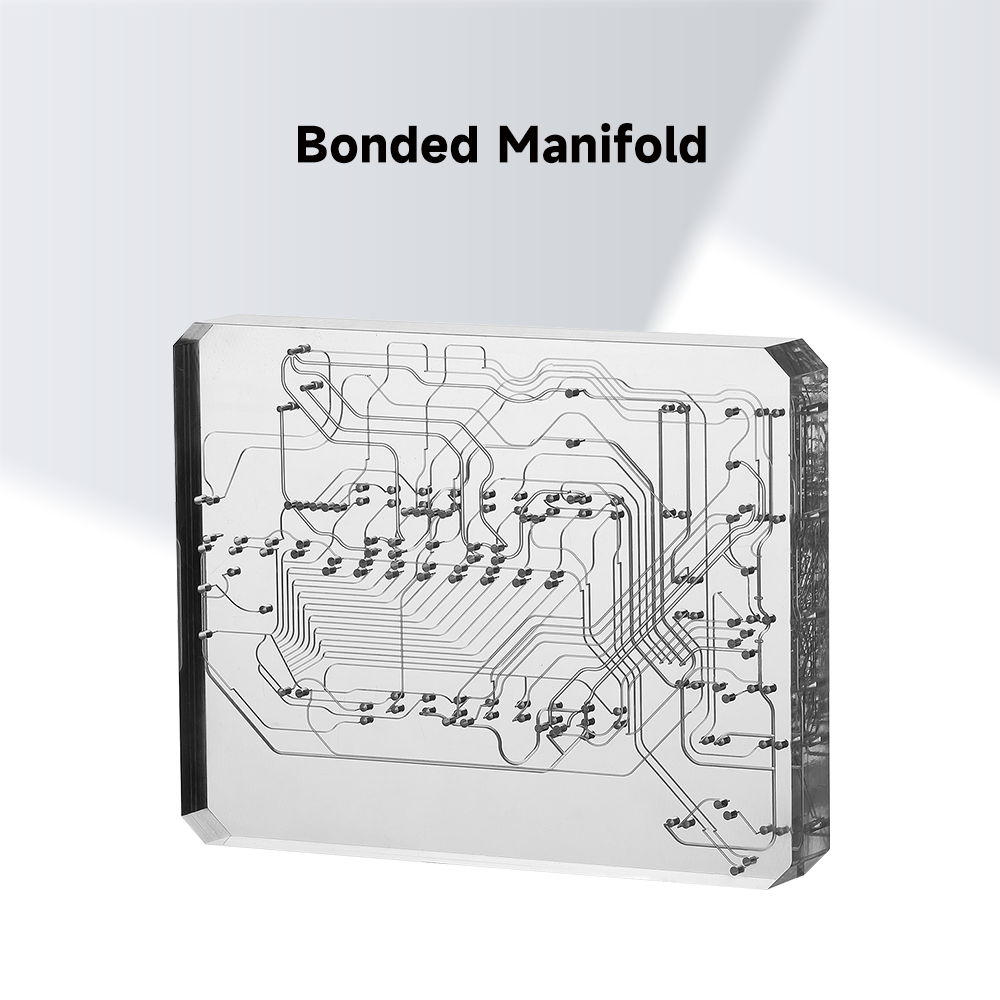

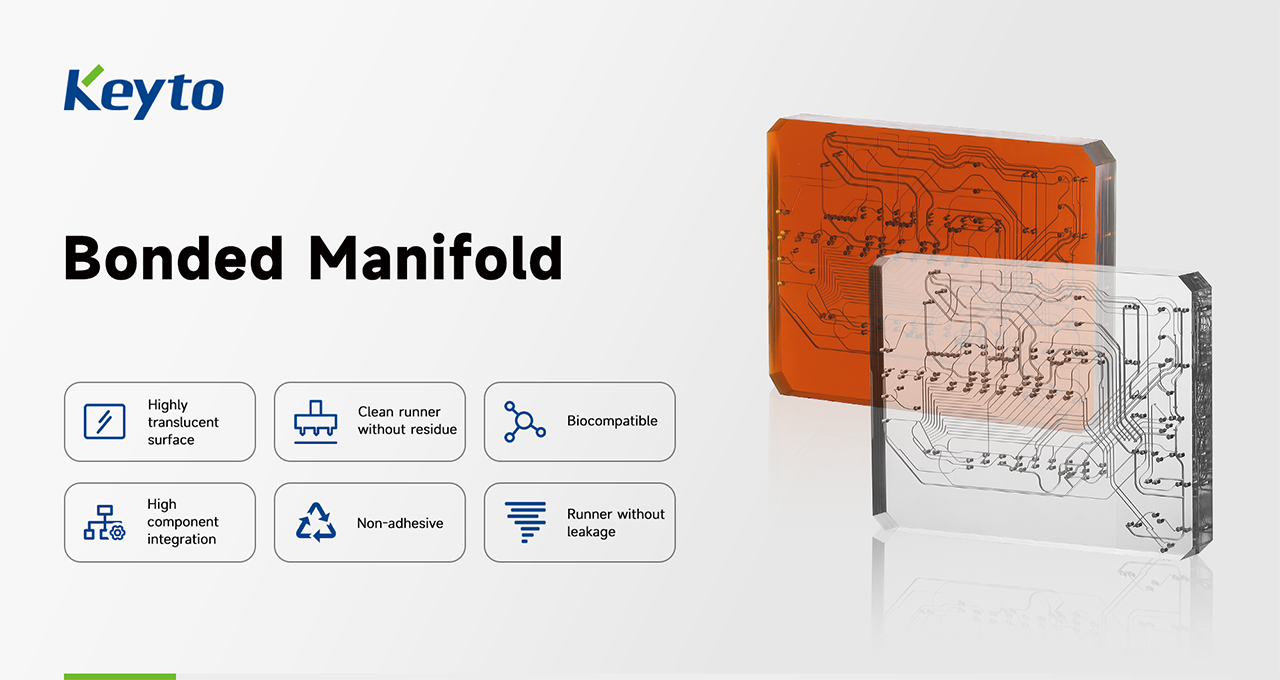

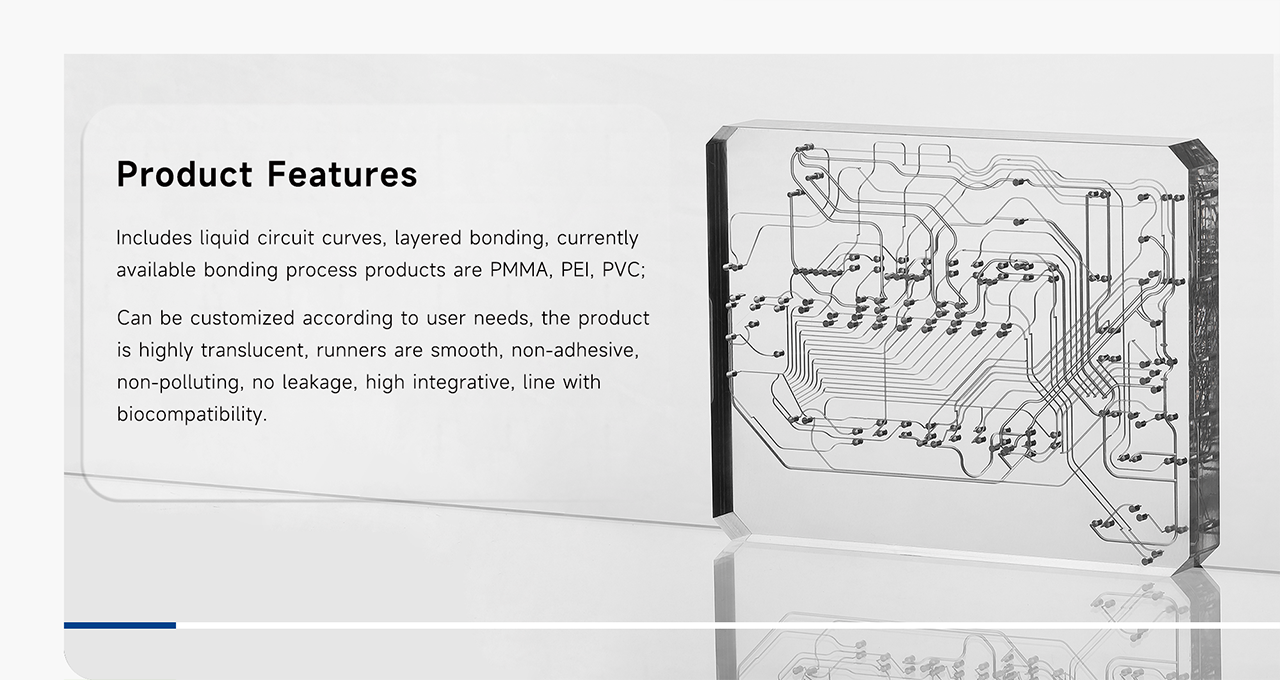

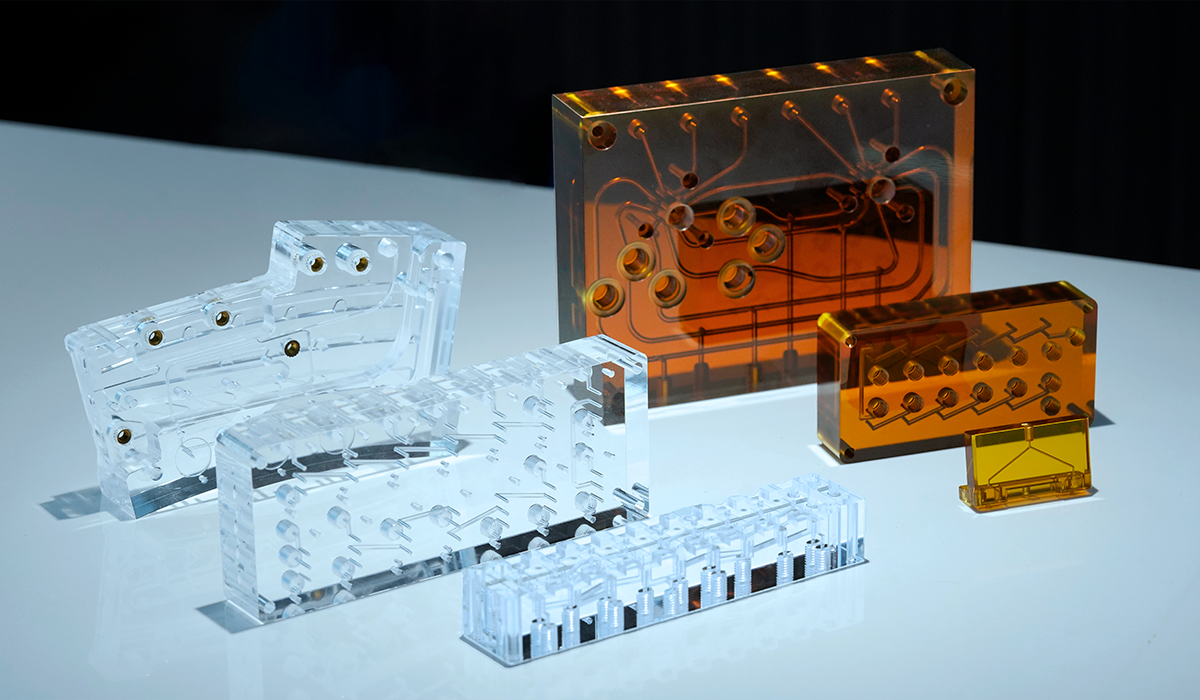

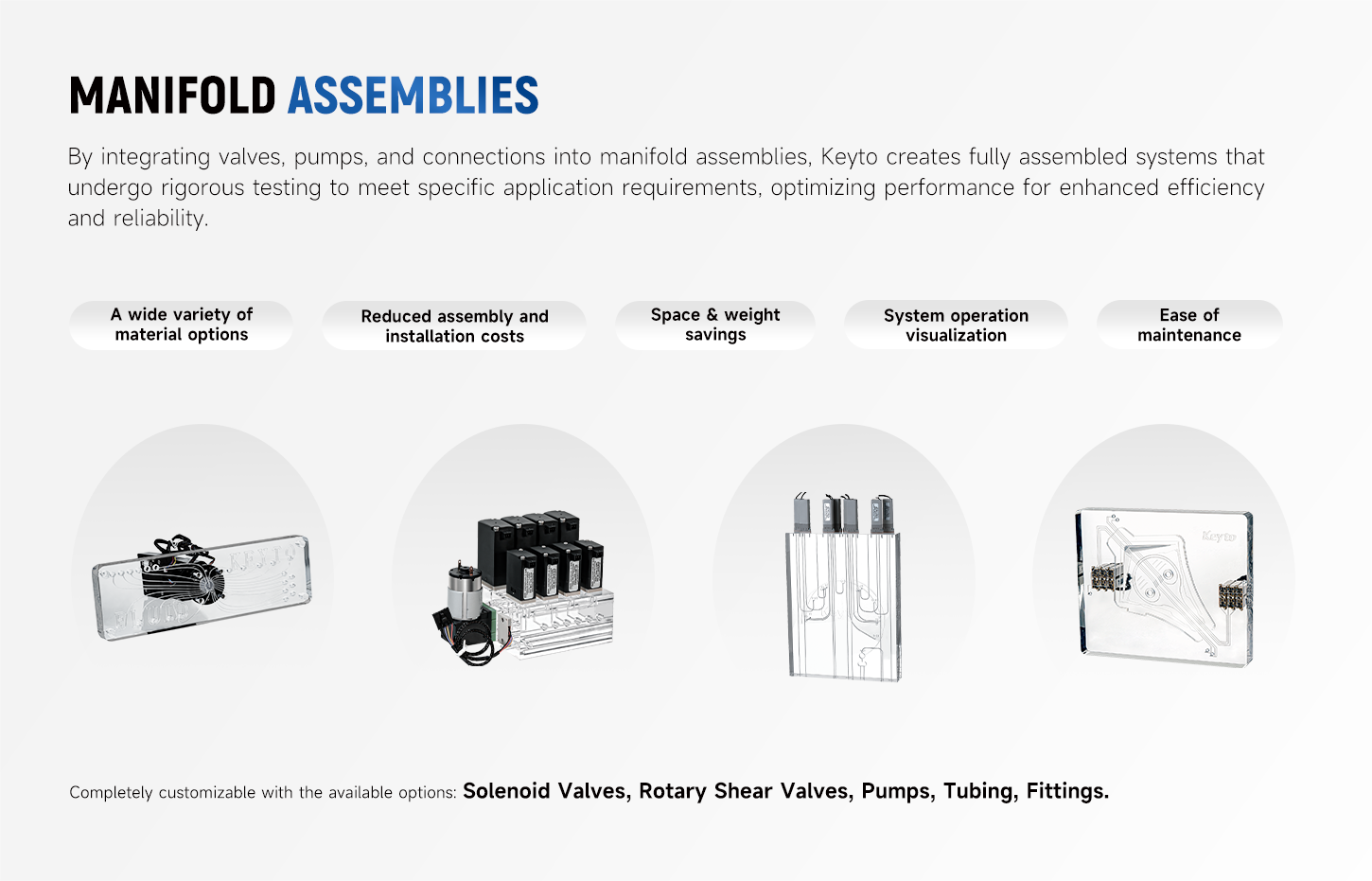

Diffusion-bonded multi-layer construction (up to 5 layers) for compact fluid routing

-

Transparent PMMA for visual verification and easier troubleshooting

-

Minimum channel feature down to 0.5 mm with ±0.01 mm channel tolerance (design dependent)

-

Square / round / D-shaped channel options to balance dead volume and flow resistance

-

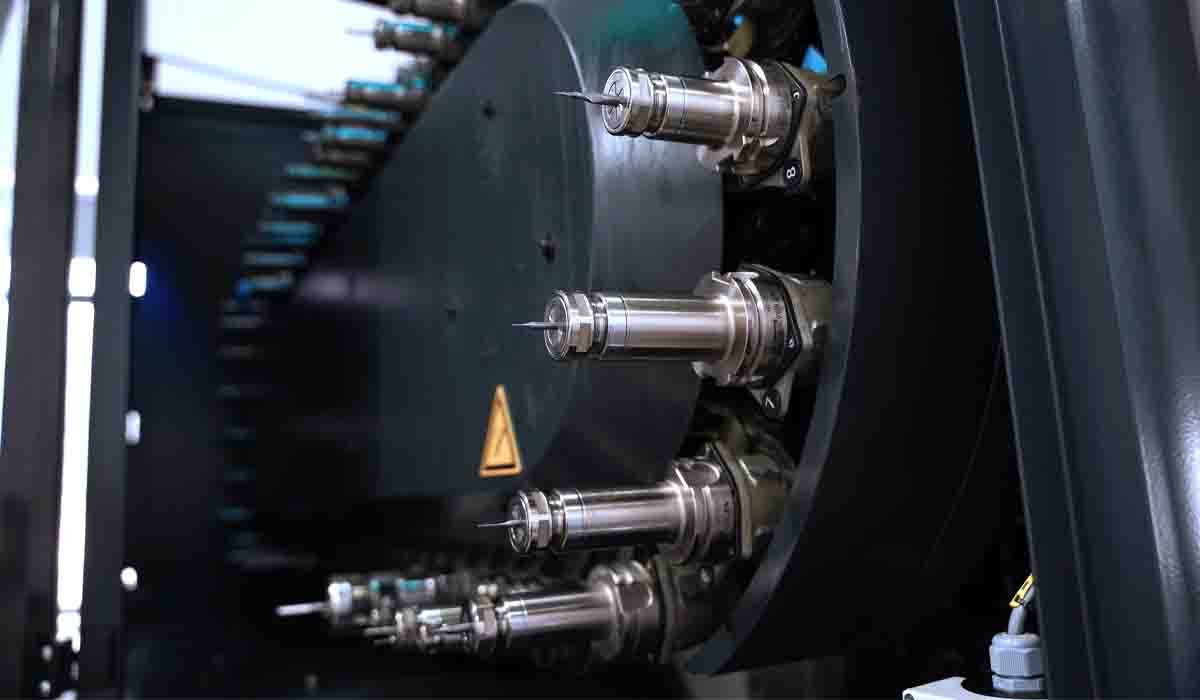

Supports dilution, mixing, reaction routing, separation, and detection workflows

-

Custom design support: send 2D/3D CAD for DFM feedback and rapid prototyping

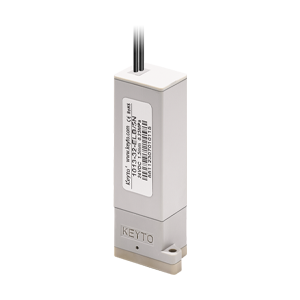

Q1: Why choose PMMA for a bonded manifold?

A: PMMA offers high clarity for visual inspection, making it ideal for prototyping, optical-friendly setups, and development-stage validation.

Q2: What bonding methods do you support?

A: We support diffusion bonding, solvent bonding, laser bonding, and ultrasonic bonding—selected based on material and application needs.

Q3: What files should I provide for quotation and review?

A: 2D drawings (PDF/DXF) and/or 3D models (STEP/IGES) plus target media, temperature, and pressure conditions.

Q4: Can you optimize the design for low dead volume?

A: Yes. We can propose channel and cavity optimizations to reduce dead zones, stabilize flow, and improve consistency.

language

language