-

Home

-

Products and Solutions

-

Keyto Global

-

News Center

-

Service Support

-

About Us

-

Contact Us

-

语言

Feature Bullets

-

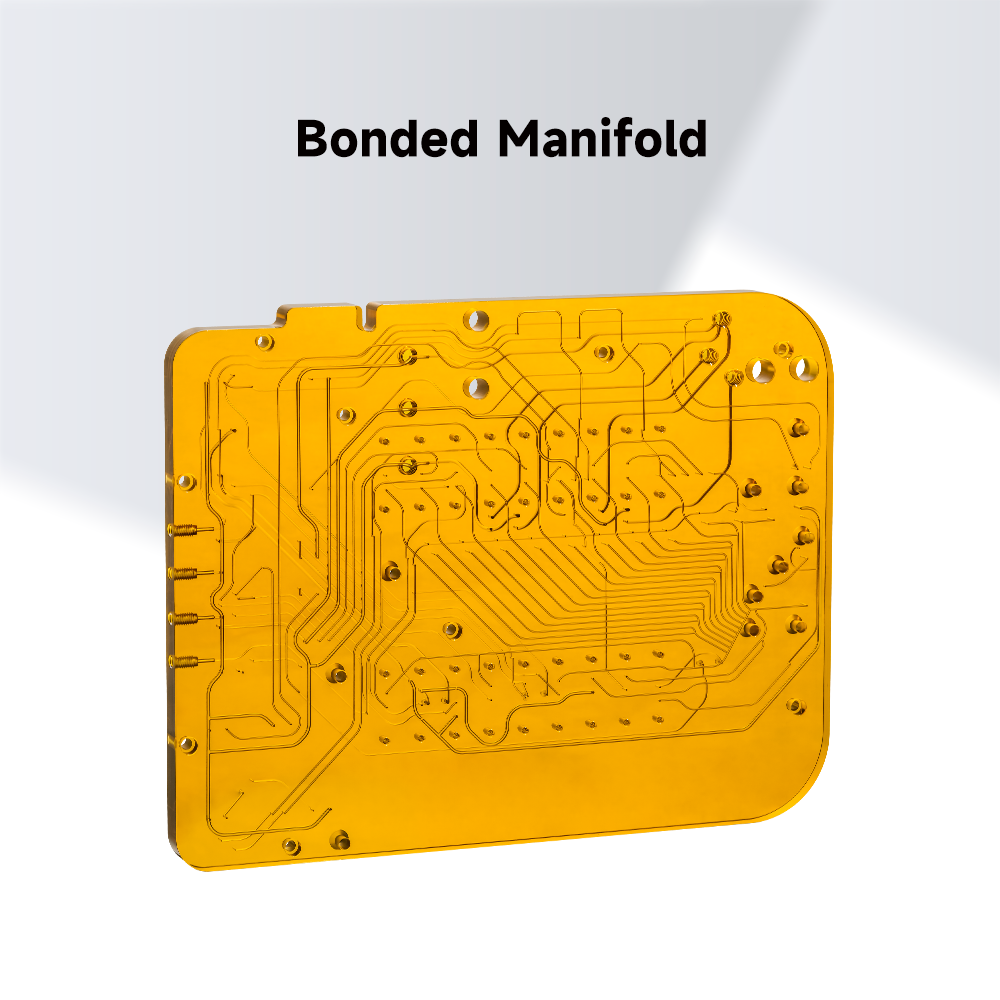

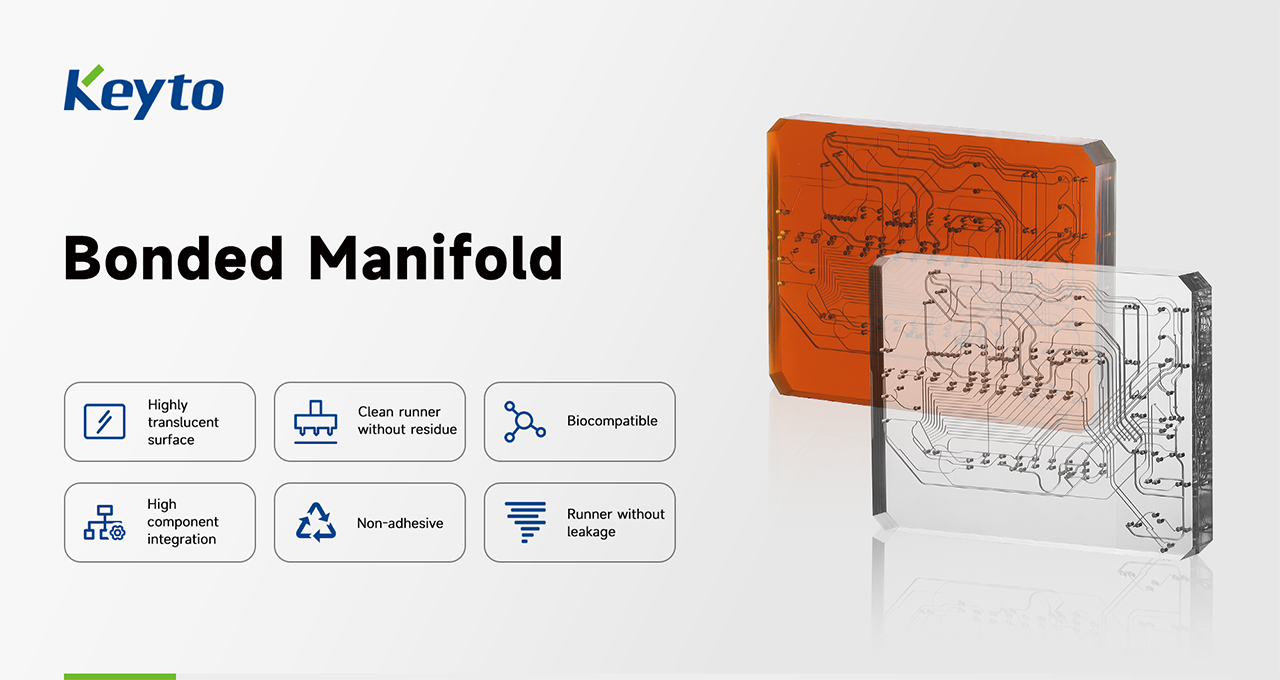

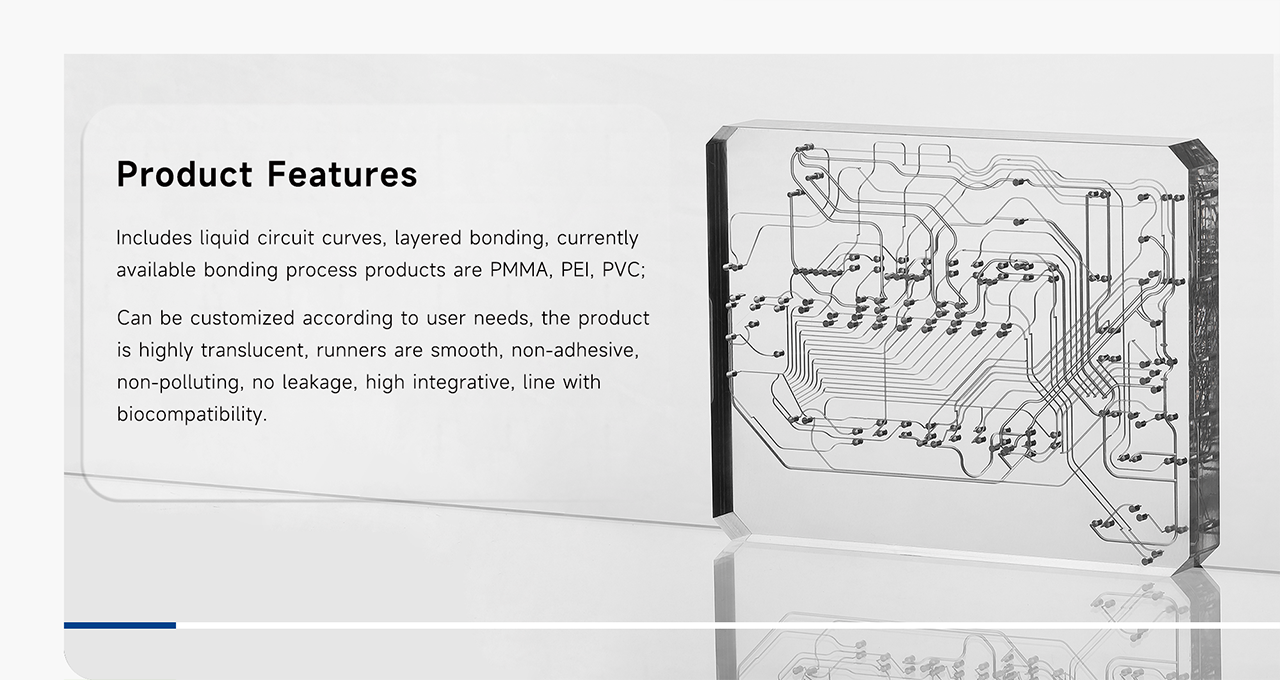

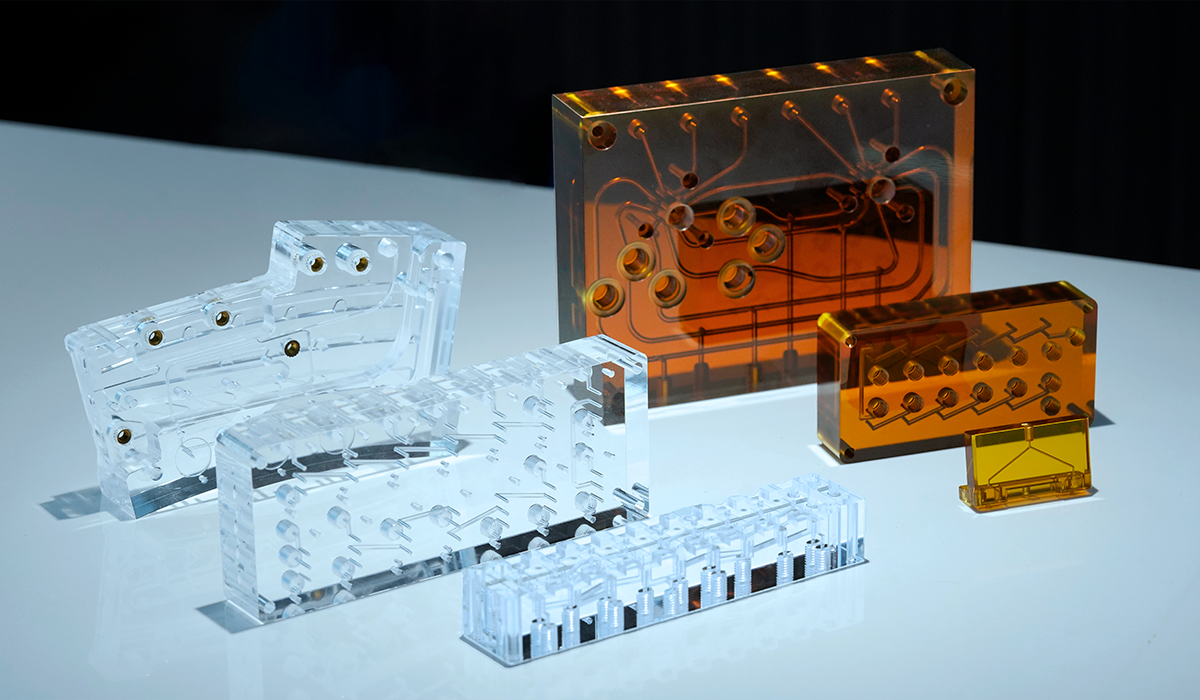

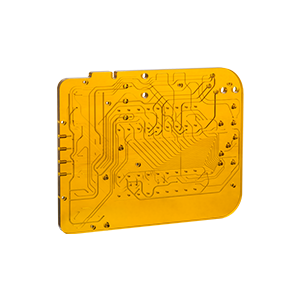

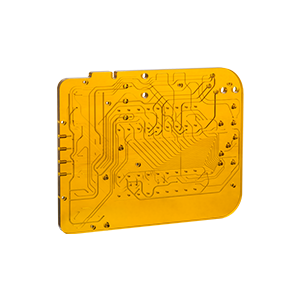

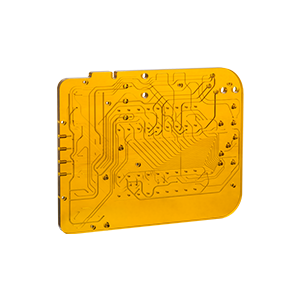

Molecular diffusion bonding on PEI for robust, sealed internal flow paths

-

Up to 5-layer architecture to maximize integration density

-

Minimum channel feature down to 0.5 mm; channel tolerance ±0.01 mm (design dependent)

-

Multi-geometry channels (square/round/D-shaped) for performance tuning

-

Consolidates multiple workflow functions to reduce assembly complexity

-

Custom development support from concept to prototype and scalable production

FAQ

Q1: Why PEI (Ultem) for diffusion bonded manifolds?

A: PEI is typically selected for applications requiring stronger mechanical performance and stable structure in compact assemblies.

Q2: Can you build multi-level routing in one manifold?

A: Yes. Multi-level routing is a key advantage of bonded manifolds and helps simplify complex liquid-handling systems.

Q3: Do you provide DFM suggestions?

A: Yes. We provide channel/layout feedback to improve manufacturability, sealing reliability, and performance consistency.

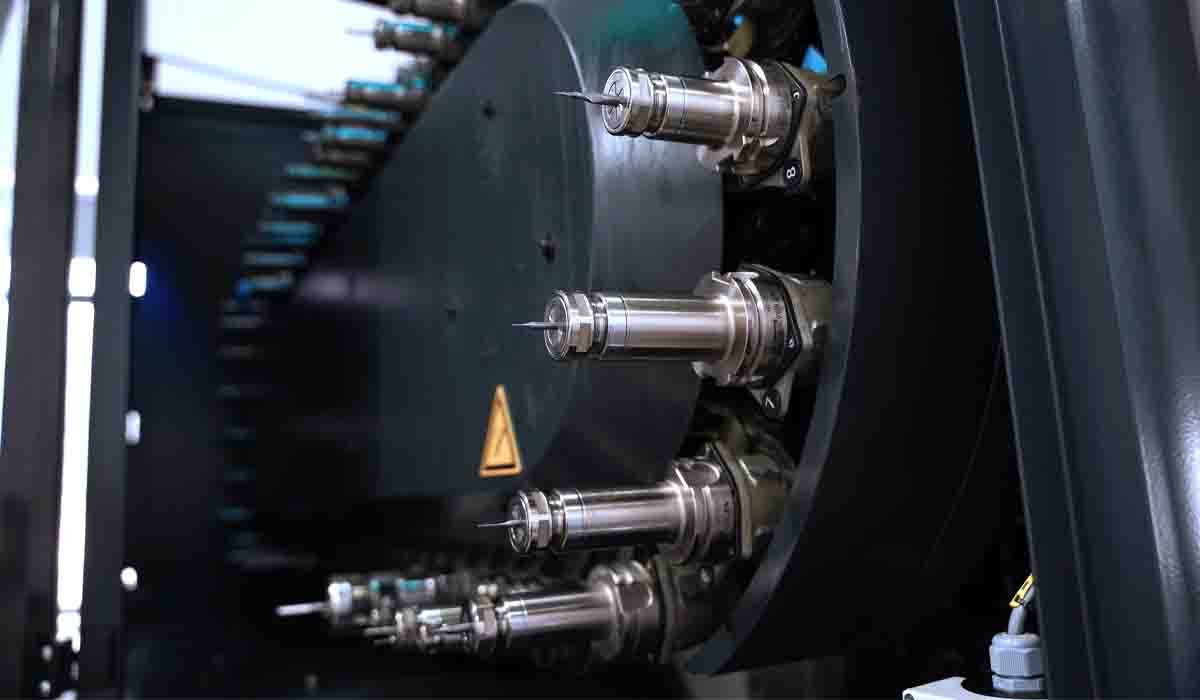

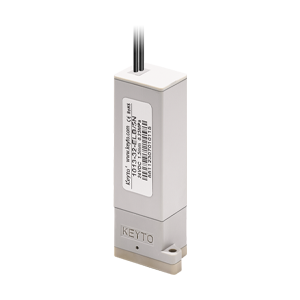

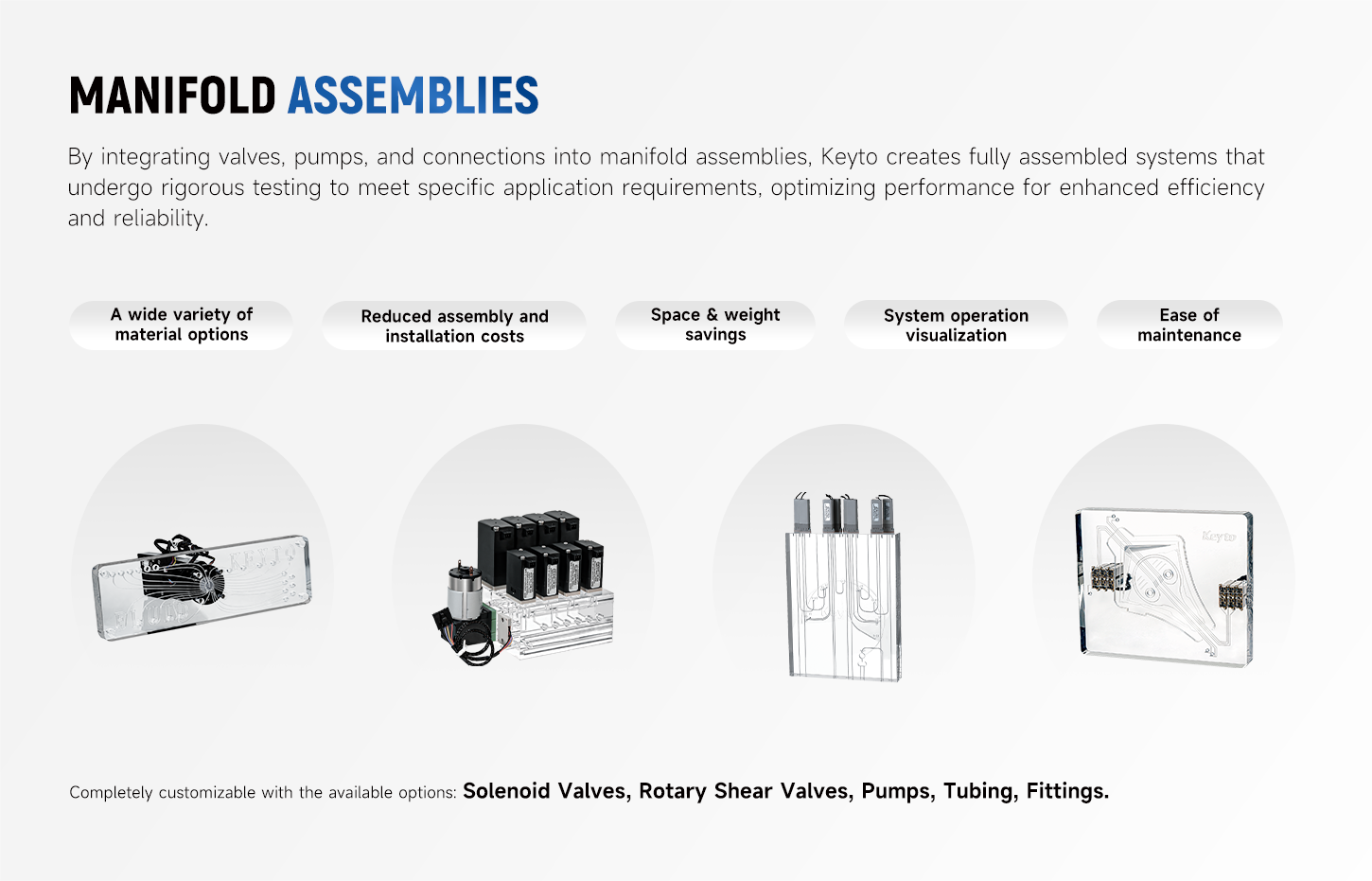

A: Yes. PEI manifolds are often used as a fluidic base for integrating valves, pumps, and connectors in a higher-level assembly.

language

language