-

Home

-

Products and Solutions

-

Keyto Global

-

News Center

-

Service Support

-

About Us

-

Contact Us

-

语言

Feature Bullets

-

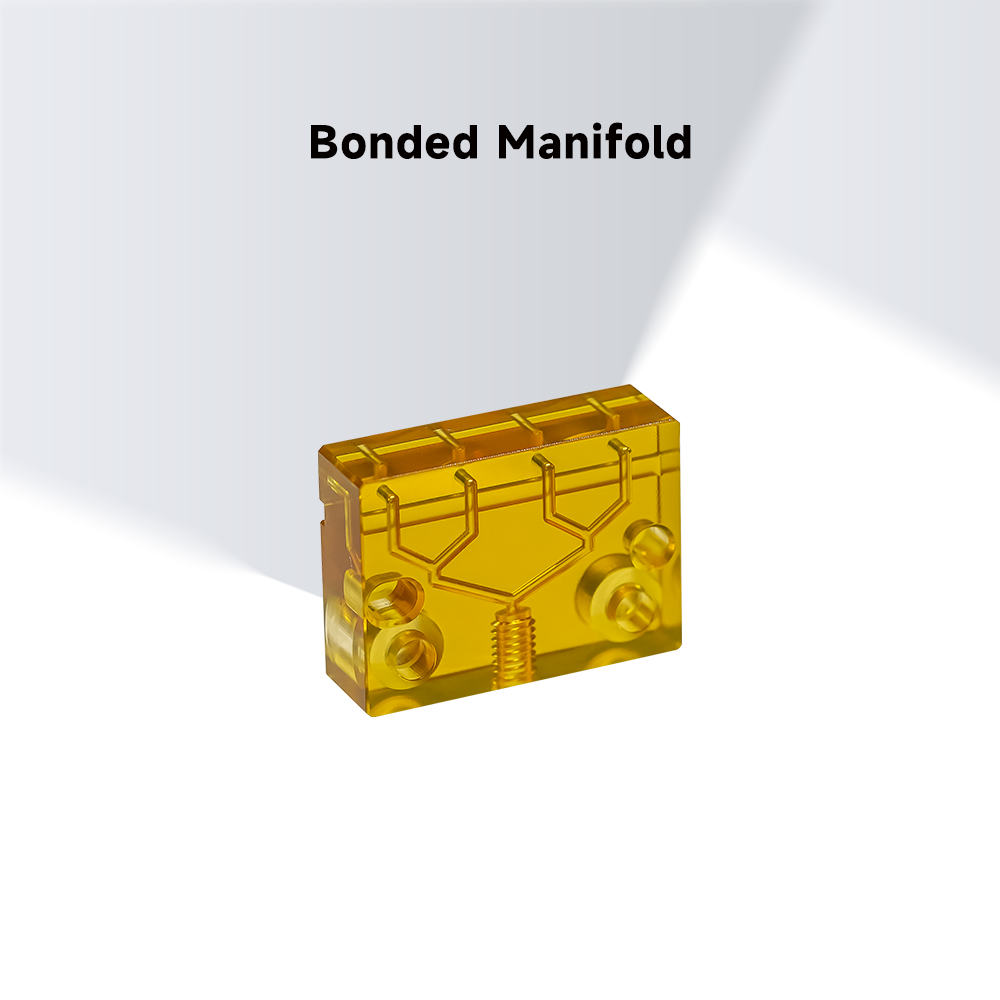

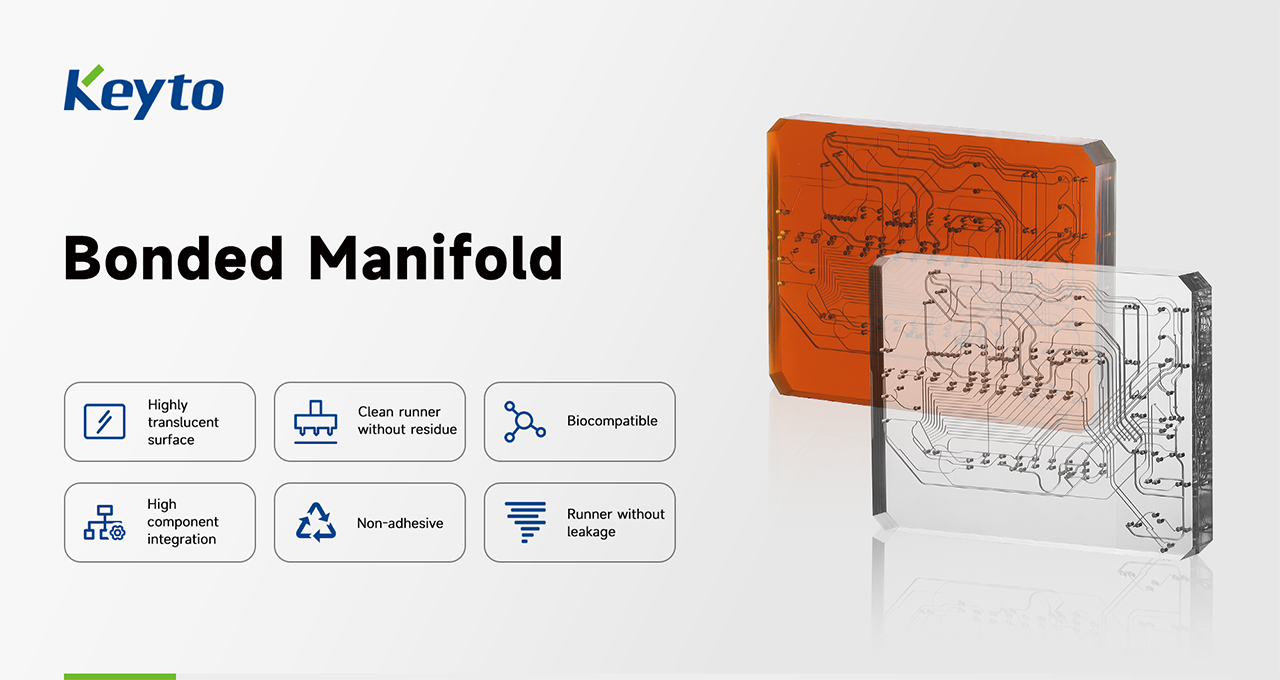

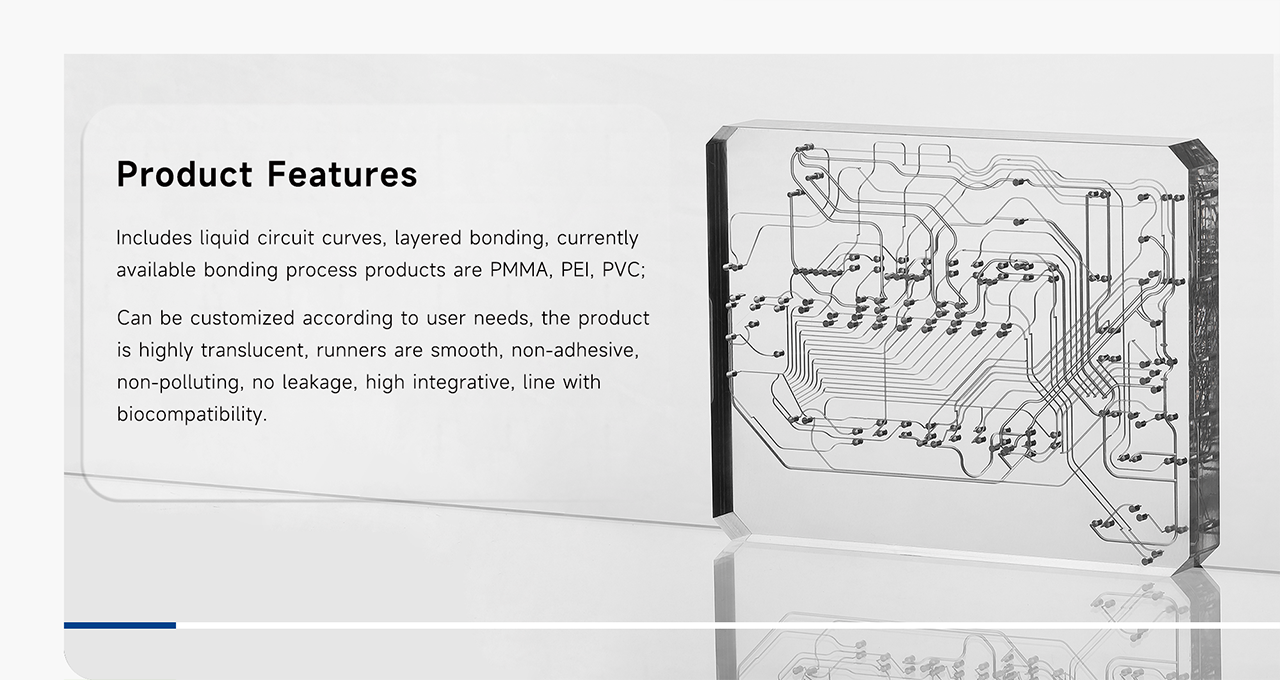

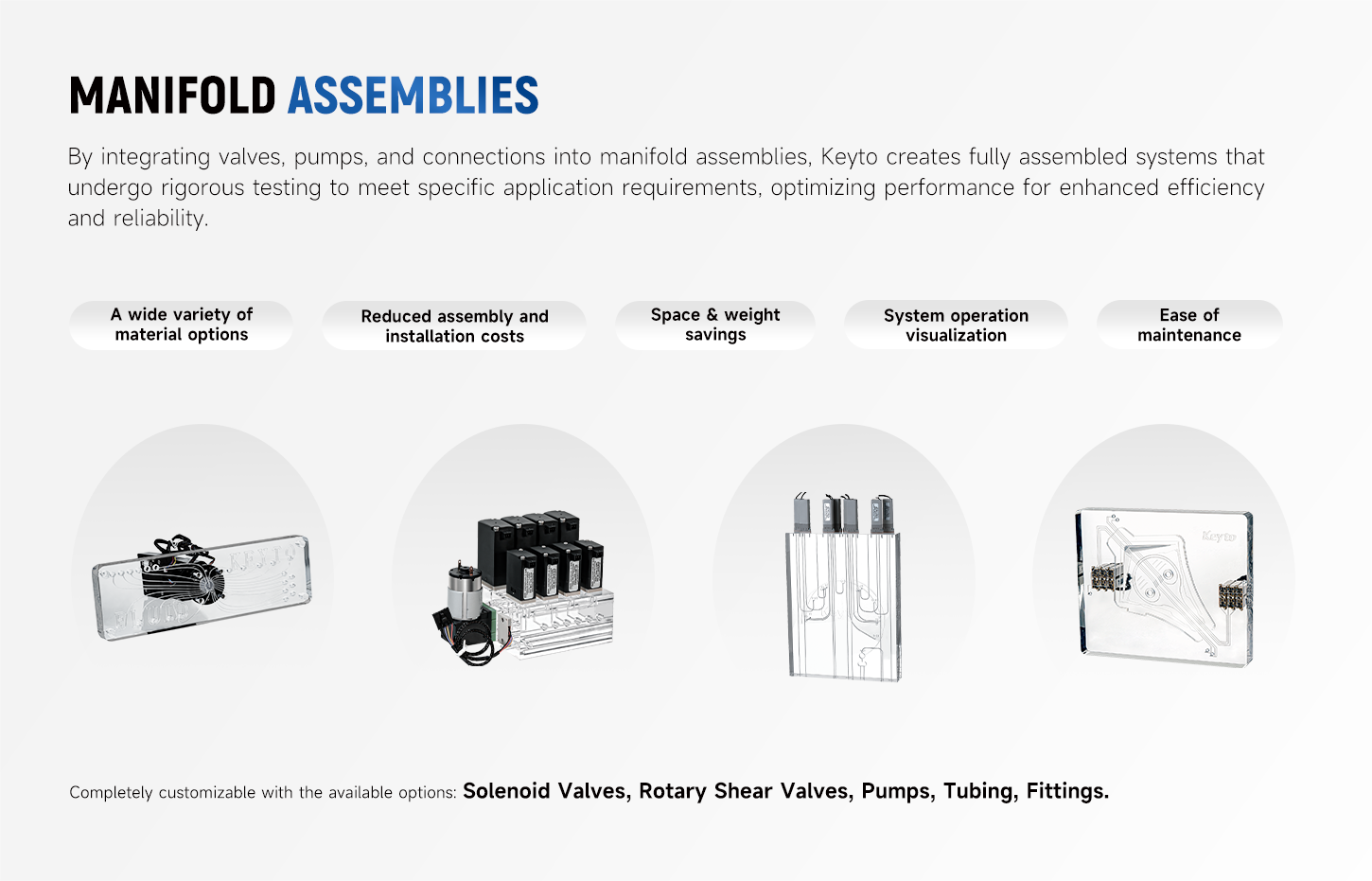

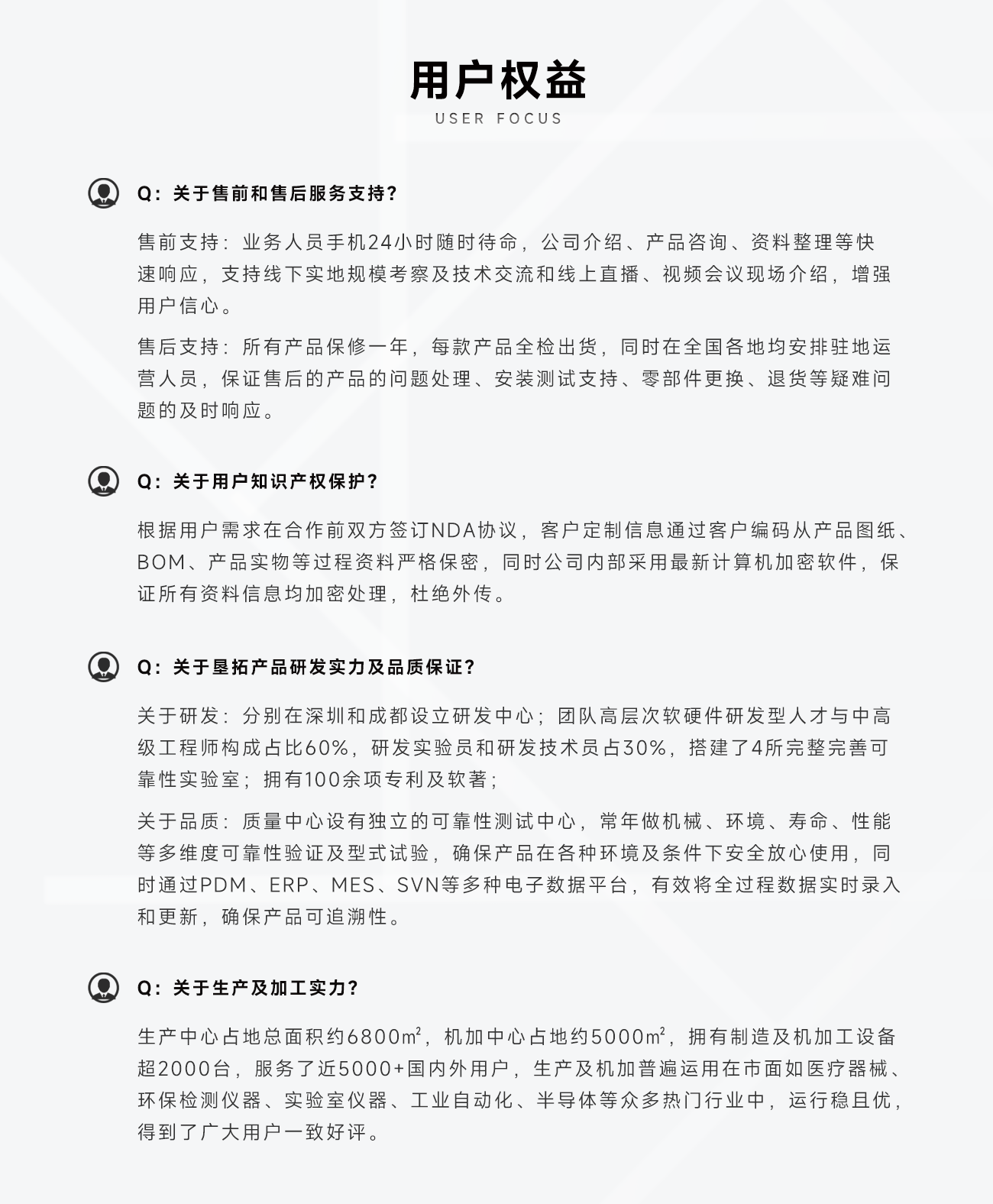

Designed for stable, scalable custom designs and production readiness

-

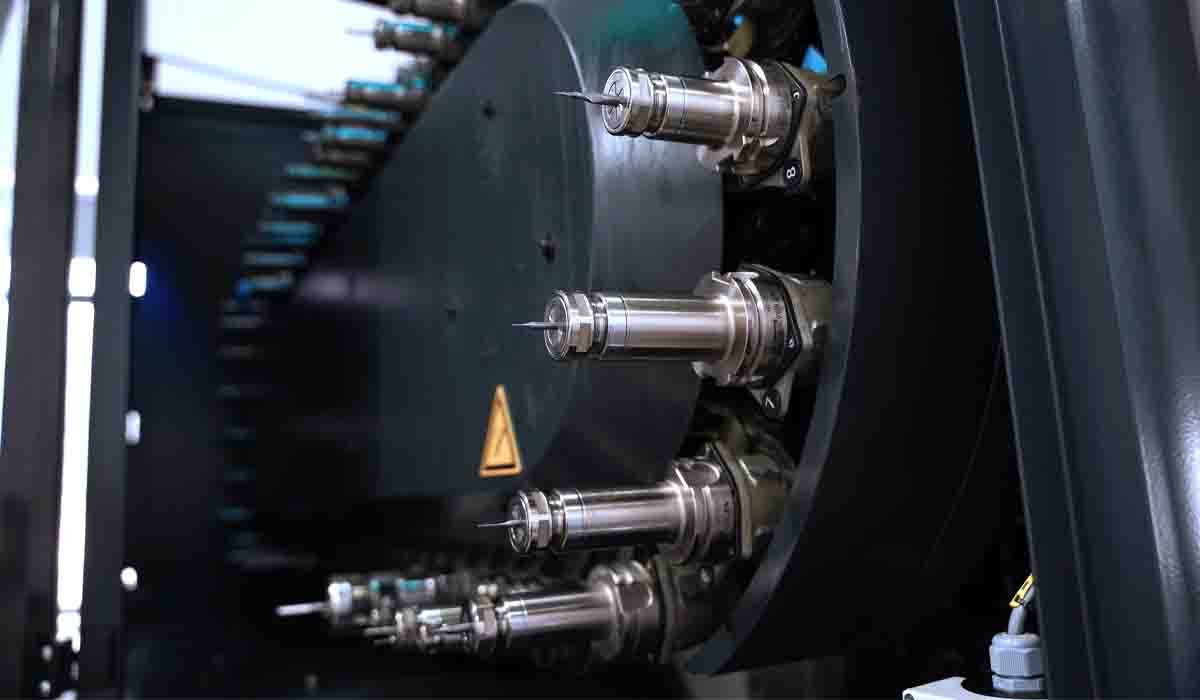

Up to 5-layer diffusion bonded routing for compact system architecture

-

0.5 mm minimum channel feature; ±0.01 mm channel tolerance (design dependent)

-

Channel shape options for resistance and dead-volume optimization

-

Consolidates multiple workflow steps to reduce assembly complexity

-

CAD-driven DFM review to improve manufacturability and consistency

FAQ

Q1: Can PEI-7 support scale-up after prototyping?

A: Yes. PEI-7 is positioned for projects moving from validation to repeatable manufacturing.

Q2: What bonding technologies are available if diffusion bonding isn’t ideal?

A: We can also apply solvent bonding, laser bonding, or ultrasonic bonding depending on material and design constraints.

Q3: Can you accommodate custom port standards?

A: Yes. Port types and positions can be customized to match your connectors, tubing, or device interfaces.

Q4: How do you ensure design consistency across batches?

A: Consistency is achieved through controlled channel geometry, manufacturability review, and validation aligned with your requirements.

language

language