-

Home

-

Products and Solutions

-

Keyto Global

-

News Center

-

Service Support

-

About Us

-

Contact Us

-

语言

Products

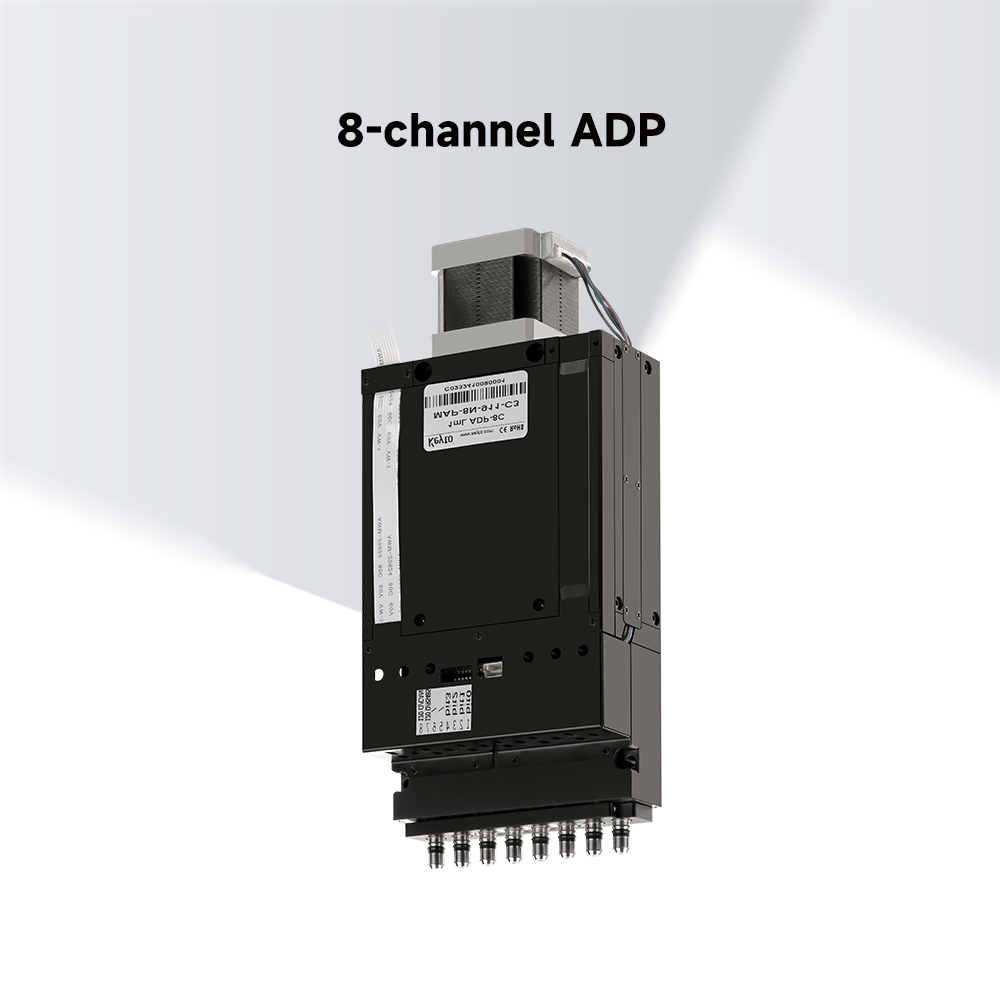

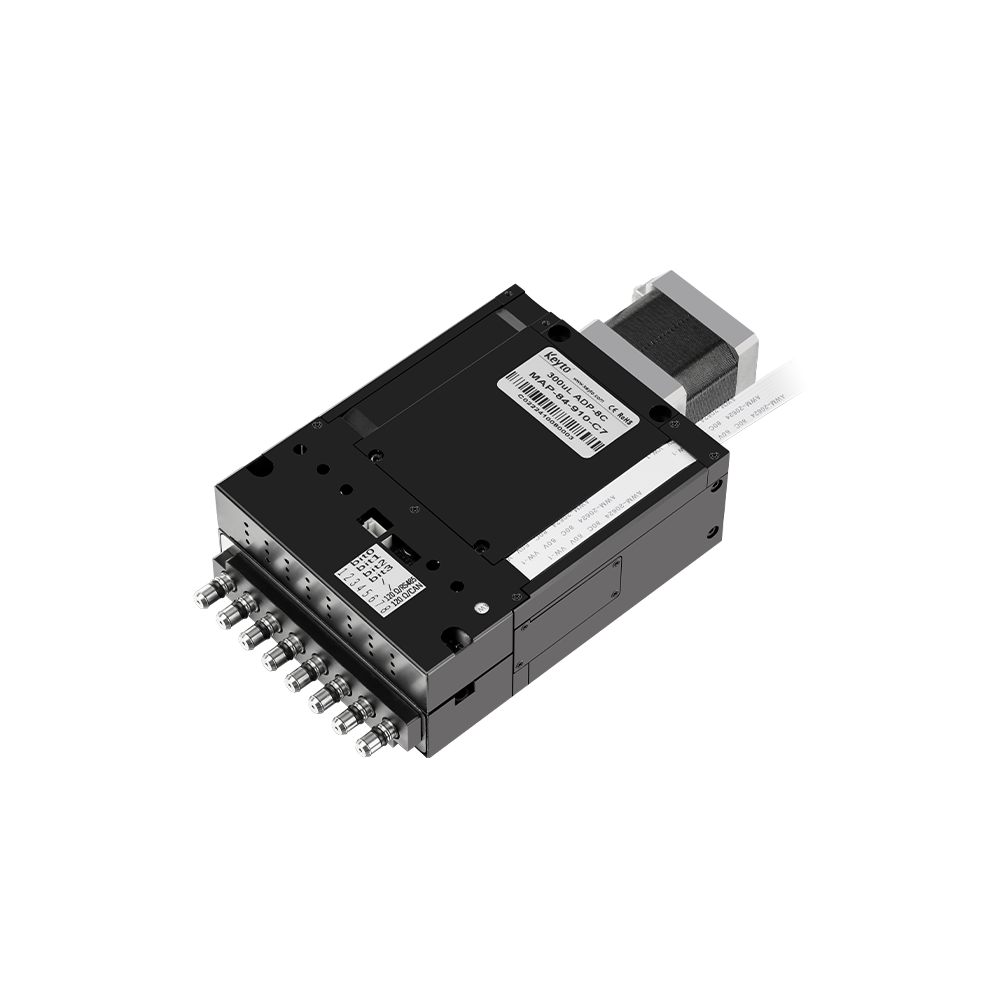

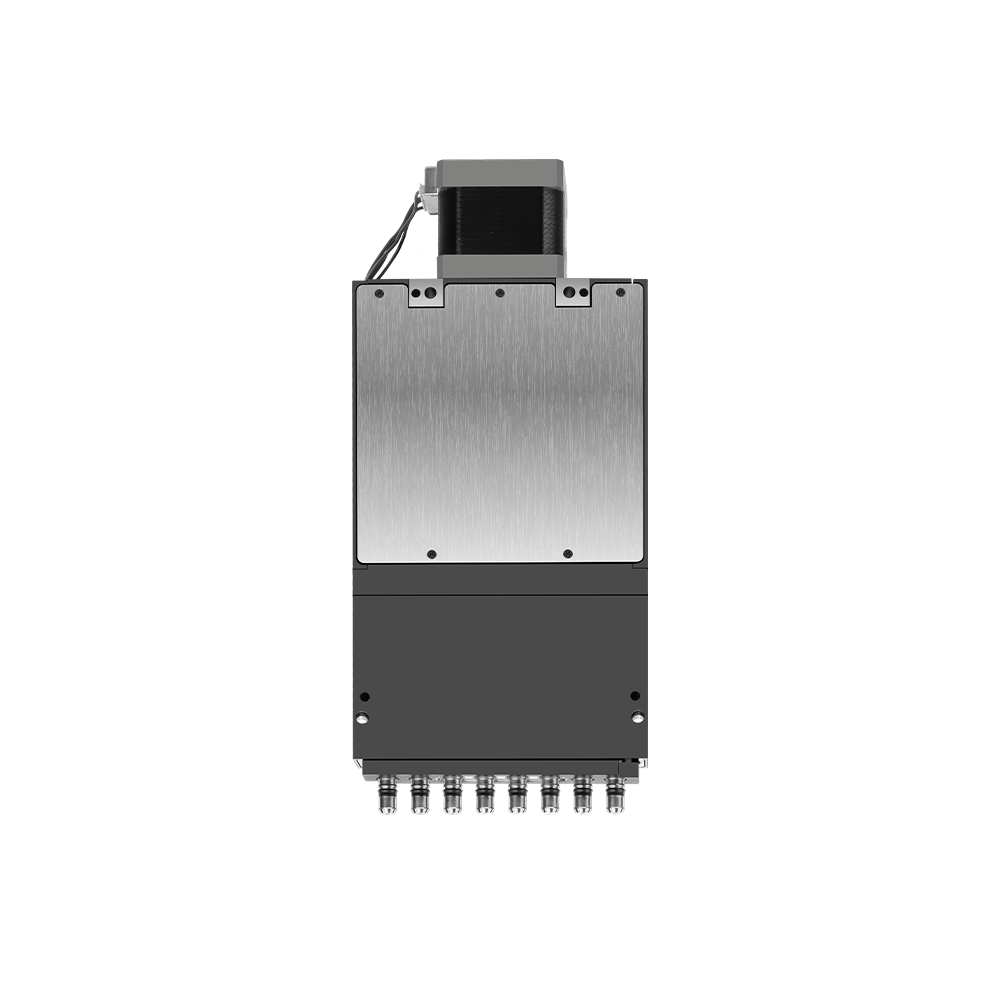

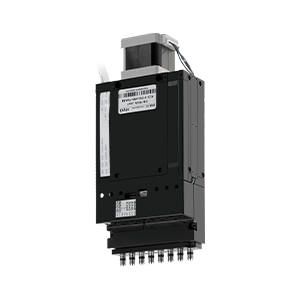

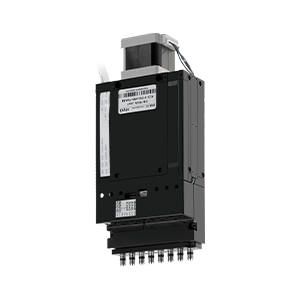

8-channel Pipette

8-channel Pipette

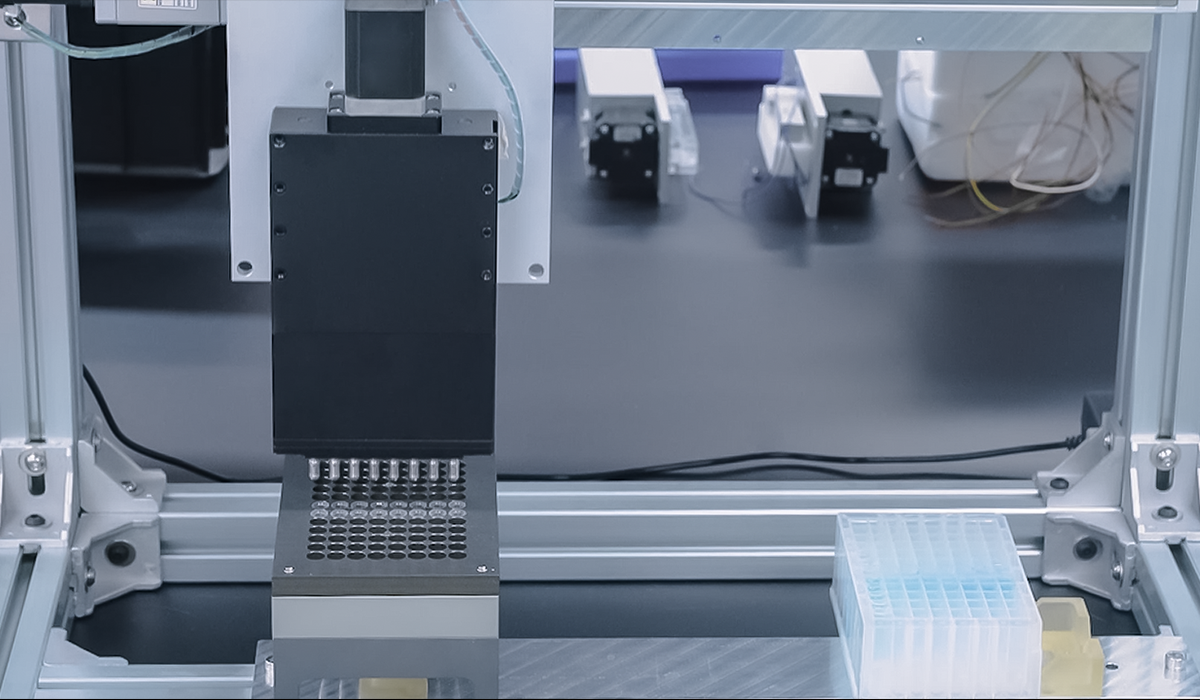

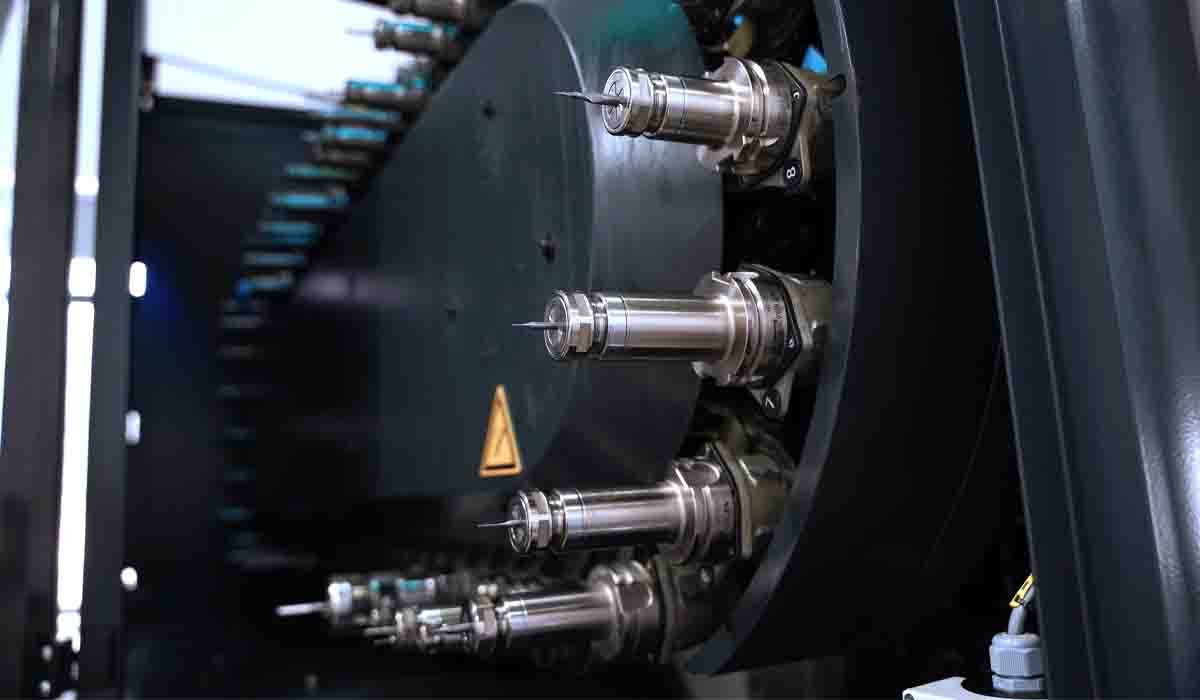

Keyto 8-channel Pipettor delivers 3-300uL or 5–1000µL precise liquid handling, integrated driving controller with CAN/RS485 interfaces, optional pressure liquid level detection, automatic TIP ejection. The pipetting barrel's service life exceeding 1 million cycles without maintenance. Compact and desigened for flexible integration, 8-channel Pipettor ensures high-performance and reliable contamination-free pipetting suitable for sensitive diagnostic platforms and automated liquid handling systems.

Key Parameters:

Configuration

Reference Model:

51AP-8

SPEC

WhatsApp Contact

E-mail

Comparison/Performance

E-mail

Comparison/Performance

Online Message

8-channel Pipette

Comparable Products

Comparison/Performance

Back

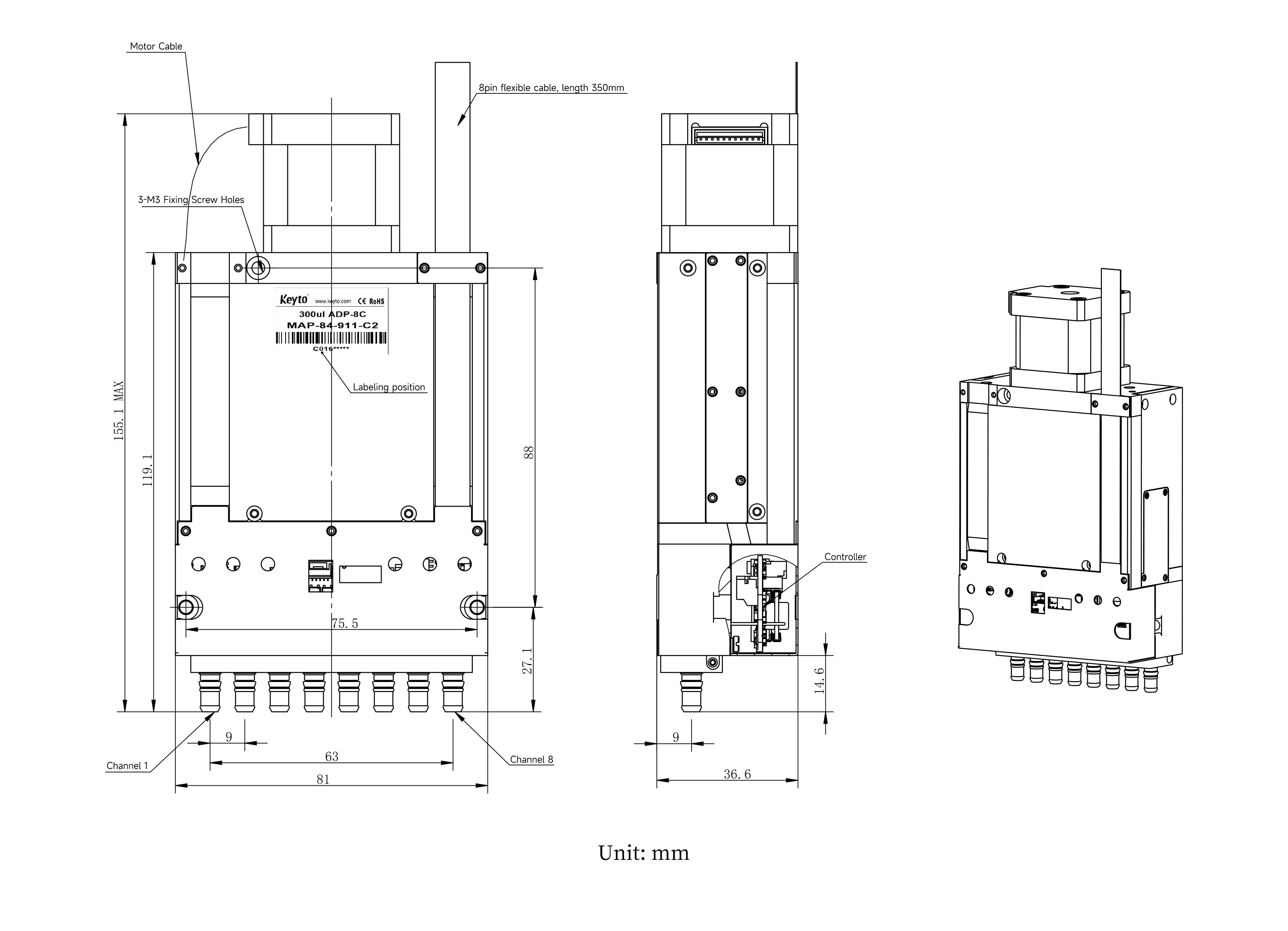

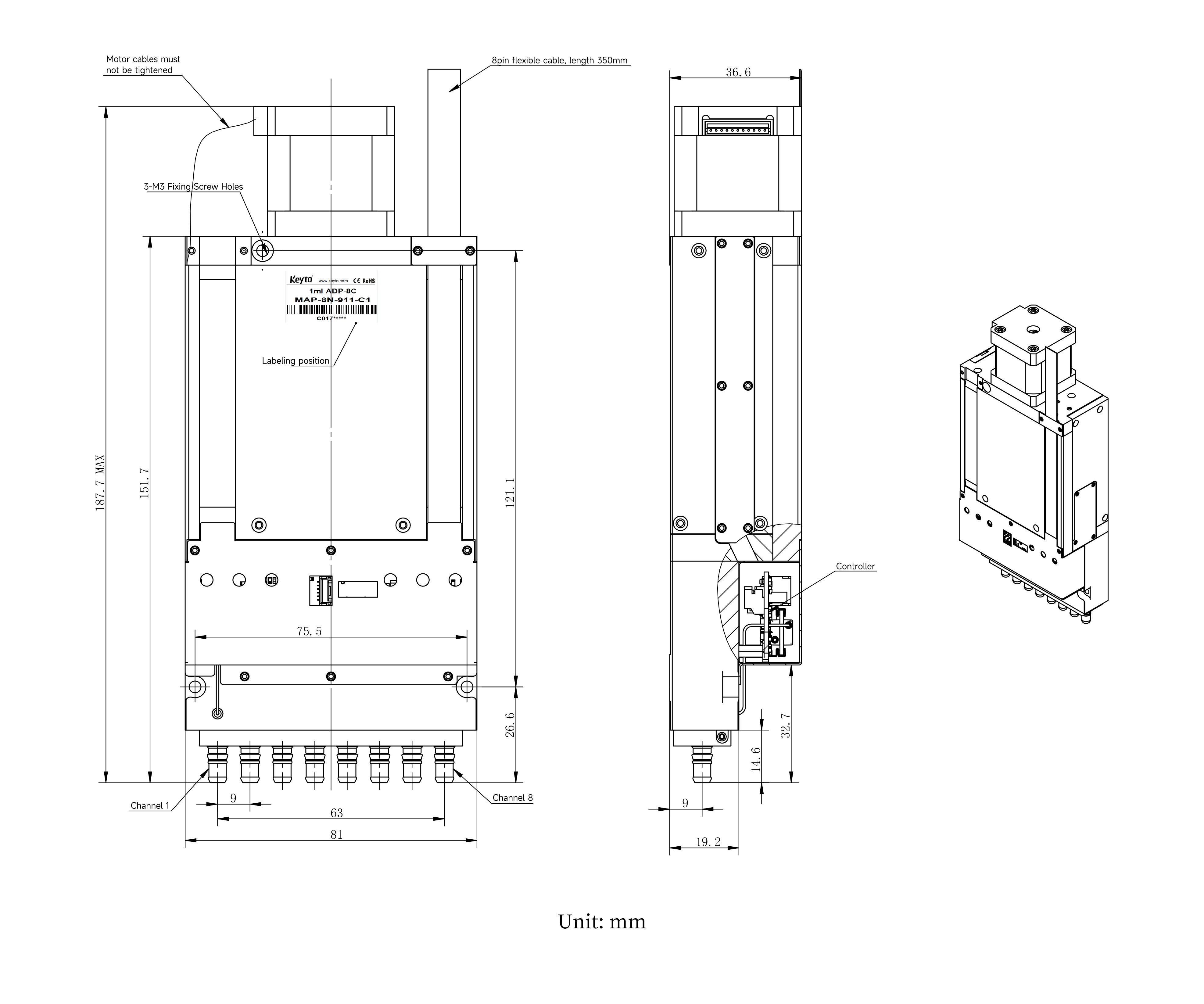

Drawings

Specifications

Overview

2D View

3D View

The pipette features dual guide shaft structure ensuring smooth movement stability. A lead screw mechanism drives the push plate along guide shafts, enabling precise control through stepper motor rotation steps for accurate liquid aspiration and dispensing.

Key Features:

Capacity Options: Available in 300μL and 1000μL for versatile laboratory applications.

Superior Accuracy: Maintains exceptionally high and stable precision throughout the entire product lifecycle.

Precise Stroke Control: Plunger aspiration/dispensing stroke of 25mm/36mm, tip ejection stroke of 9.5mm/8.6mm for optimal performance.

Optical Position Detection: Advanced photoelectric sensors detect plunger initial position and tip ejection status for reliable operation monitoring.

High-Performance Motor: Long-life 1.8° two-phase stepper motor ensures consistent performance and reliability.

Automatic Tip Ejection: Integrated automatic tip removal functionality for enhanced workflow efficiency.

Extended Durability: Advanced cylinder machining technology, rigorous testing procedures, and unique sealing solutions guarantee 1 million cycles lifespan without maintenance requirements.

Chemical Resistance: Tip-contact components feature excellent chemical resistance and wear properties, eliminating tip adapter replacement needs throughout product lifecycle.

Demo video

Product video

Factory video

Recommended

3D Model

3D Model Download

*Please leave your contact information if you want to download confidential documents.

3D Model

3D Model Download

*Please leave your contact information if you want to download confidential documents.

Format

Position

E-Mail

language

language