-

Home

-

Products and Solutions

-

Keyto Global

-

News Center

-

Service Support

-

About Us

-

Contact Us

-

语言

Products

Keyto SP18P Air Displacement Pipette | 2–1000µL Precise Liquid Handling | Liquid Level Detection

Keyto SP18P Air Displacement Pipette | 2–1000µL Precise Liquid Handling | Liquid Level Detection

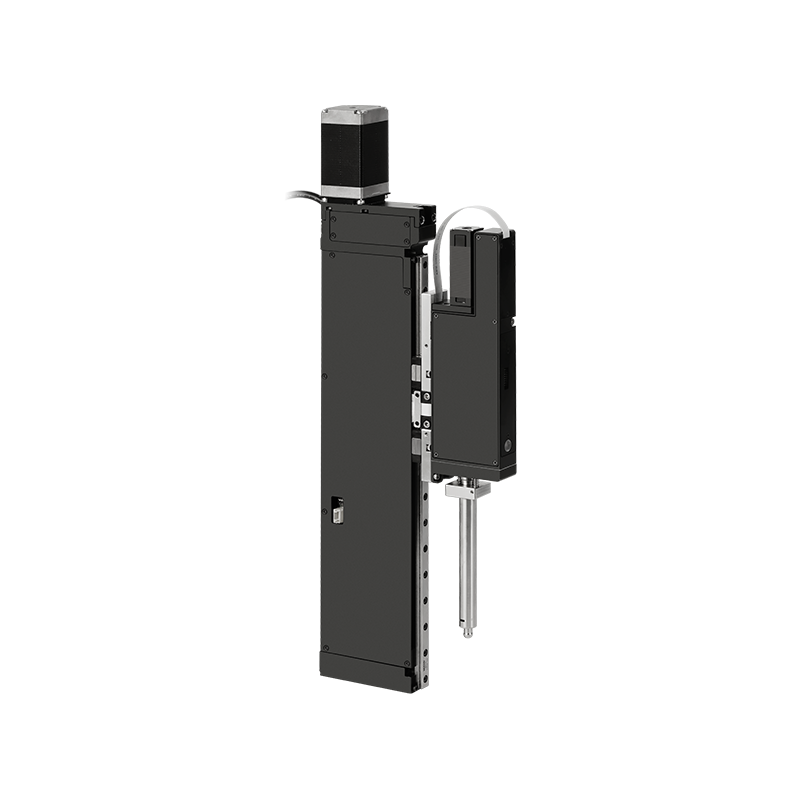

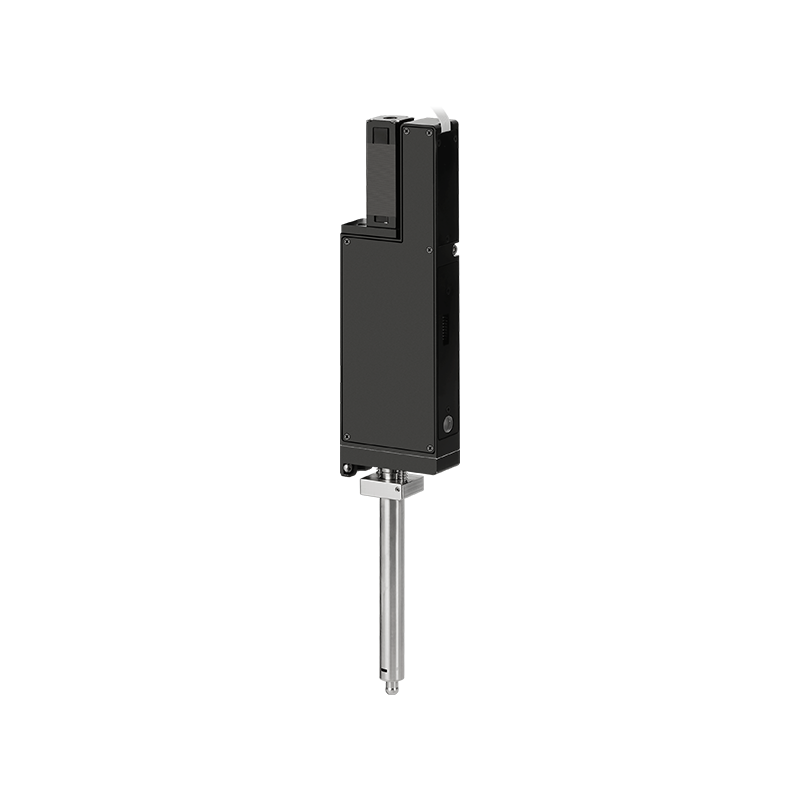

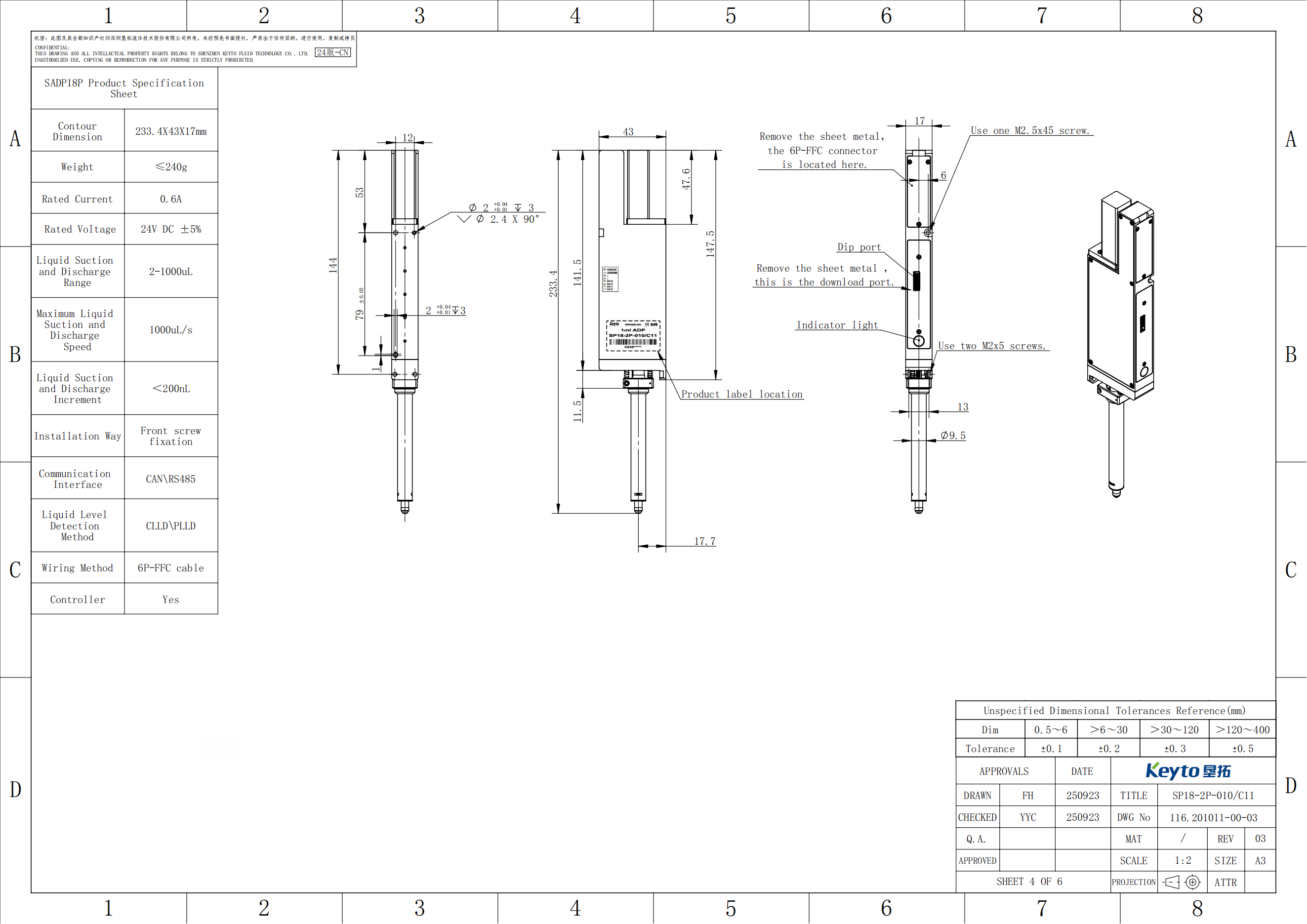

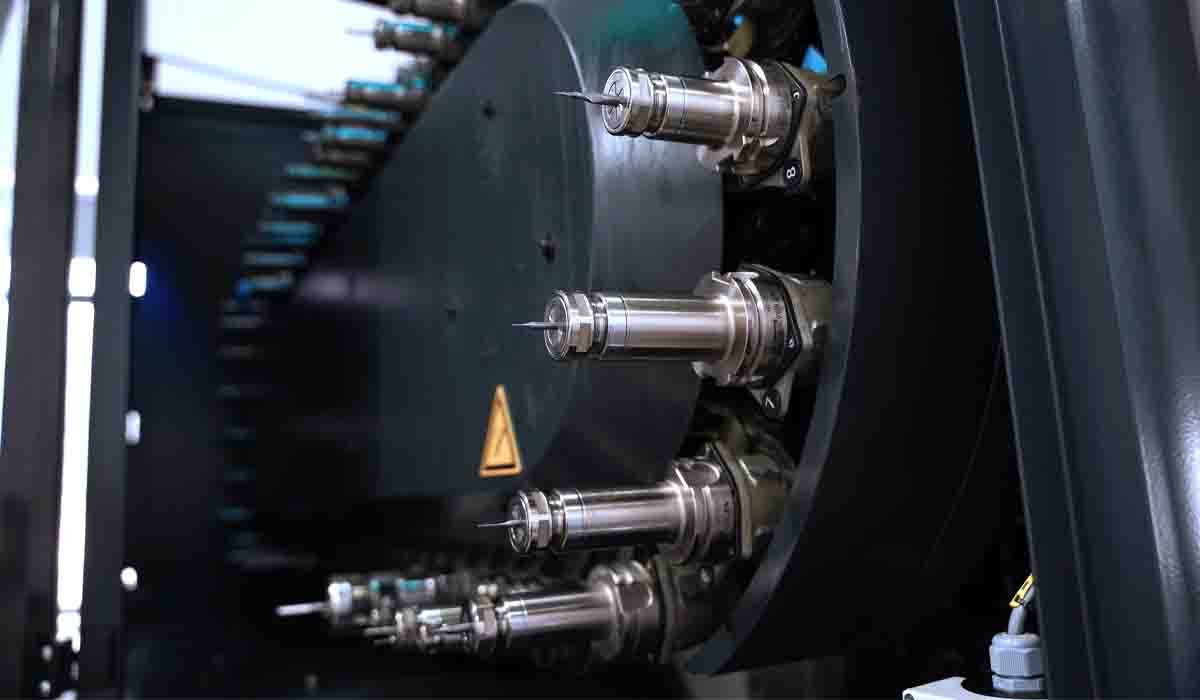

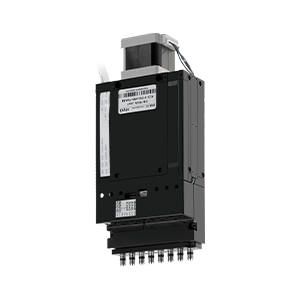

SP18P(Superb Air Displacement Pipettor 18 Plus) delivers 2–1000µL precise liquid handling with independent channel movement of 18mm TIP to TIP spacing. This lightweight 240g module integrates driving controller with CAN/RS485 interfaces, fast both pressure and capacitive liquid level detection, automatic TIP ejection, aspiration foam detection, aspiration clot detection, aspiration empty detection. The pipetting barrel's service life exceeding 1 million cycles without maintenance. Compact and desigened for flexible integration, SP18P ensures high-performance and reliable contamination-free pipetting suitable for sensitive diagnostic platforms and automated liquid handling systems.

Key Parameters:

Model Type+Volume

Reference Model:

SP18P

SPEC

WhatsApp Contact

E-mail

Comparison/Performance

E-mail

Comparison/Performance

Online Message

Keyto SP18P Air Displacement Pipette | 2–1000µL Precise Liquid Handling | Liquid Level Detection

Comparable Products

Comparison/Performance

Back

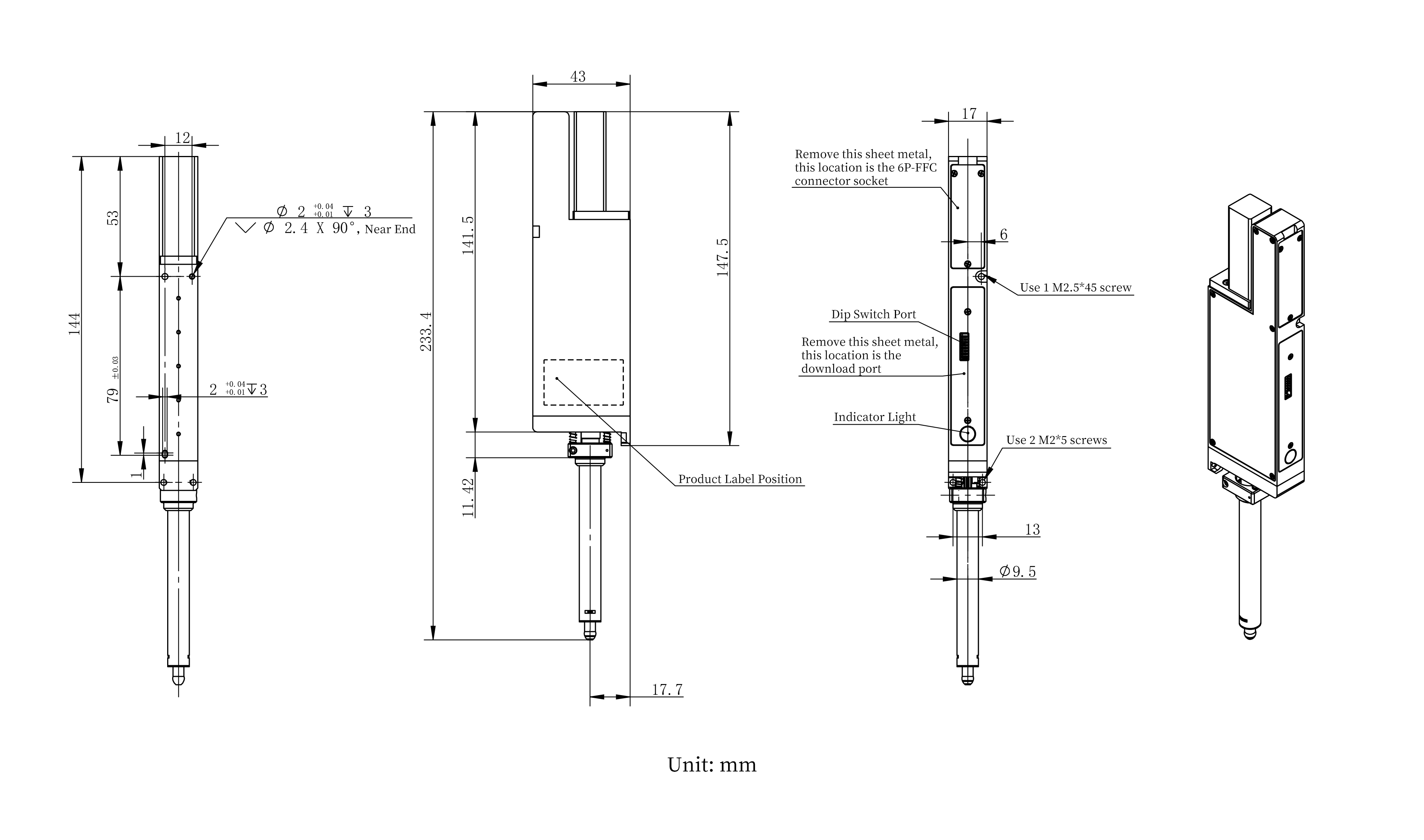

Drawings

Specifications

Overview

Repeated Liquid Level Detection:

- Mitigating Liquid Surface Fluctuations and Interference Liquid surfaces may experience micro-fluctuations due to temperature variations, reagent evaporation, or mechanical vibrations. Single detection attempts are susceptible to interference and false readings. Repeated detection eliminates errors through multiple verifications, enhancing positioning reliability.

- Preventing Equipment Damage and Sample Loss If initial detection fails due to tip misalignment or bubble interference, repeated detection can promptly correct pipetting depth, preventing tip damage from touching the container bottom or reagent waste from dry aspiration.

- Minimizing Tip Consumption Maximizes tip utilization by enabling multiple detection cycles with a single tip, optimizing consumable costs and streamlining experimental workflows while reducing waste and improving pipetting efficiency.

Capacitive/Pressure Based Hybrid Liquid Level Detection:

Capacitive sensors detect conductive liquid surfaces while pressure sensors verify liquid resistance.

- High Precision and Stability Dual detection systems maintain liquid level positioning accuracy within ±0.5mm and eliminate environmental interference (humidity drift, electromagnetic noise) through real-time calibration.

- Enhanced Fault Tolerance Multi-sensor coordination identifies liquid level anomalies, provides timely alerts, and pauses operations to reduce equipment failure rates.

- Improved Experimental Efficiency In high-speed pipetting scenarios, repeated detection completes verification without additional steps, reducing overall process time.

- Compatibility with Complex Liquid Properties Different liquids exhibit significant variations in conductivity, viscosity, and transparency (polar reagents, viscous blood, transparent buffers). hybrid LLD covers a broader range of liquid types.

Automatic Tip Pick-up/Ejection/Detection:

- Cross-Contamination Prevention Prevents pipetter execution of aspiration without tips, avoiding contamination, especially critical in high-throughput experiments (PCR, drug screening), significantly reducing cross-sample contamination risks.

- Enhanced Operational Efficiency Batch high-speed tip ejection reduces single operation time by over 30% in multi-channel pipetting scenarios, supporting continuous batch processing.

- Equipment Longevity Protection Precision mechanical control of tip ejection pressure reduces wear on pipette pump components, extending equipment lifetime.

Single Aspiration, Multiple Dispensing:

- Efficiency Optimization Eliminates frequent aspiration-dispensing cycles (such as batch aliquoting to microplates), reducing process time by approximately 40%.

- Residual Volume Control Segmented dispensing minimizes liquid retention on tip inner walls, reducing waste of high-value reagents.

9mm Parallel Configuration:

- Compact Design and Compatibility The 9mm thickness design integrates more pipettes (8-channel or 16-channel) in limited space, compatible with standard deep-well plate layouts, reducing equipment footprint while improving pipetting efficiency.

- Flexibility and Fault Tolerance Enables one-to-one correspondence of pipetting positions without system calculation of corresponding wells, reducing error probability.

Plunger-Type Cylinder Design:

- Superior Linearity and Higher Precision Plunger movement trajectory exhibits higher linear matching with motor/stepper drive signals. Software can precisely compensate displacement-flow curves, further enhancing linear performance. Compared to plunger-type designs with single-action mechanisms and external sealing structures that rely on external forces for return strokes, Plunger-type systems avoid flow attenuation at stroke endpoints that causes linearity degradation.

Demo video

Product video

Factory video

Recommended

3D Model

3D Model Download

*Please leave your contact information if you want to download confidential documents.

3D Model

3D Model Download

*Please leave your contact information if you want to download confidential documents.

Format

Position

E-Mail

language

language