+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

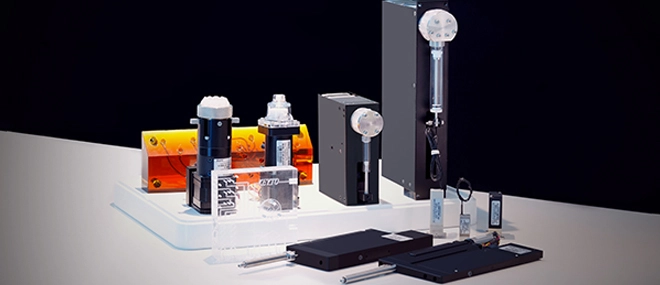

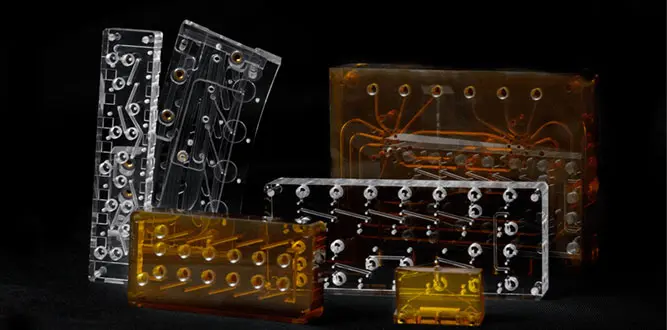

To protect the health care, lots of global diagnostics companies bring high-capacity PCR test machine which requires huge consumables including tips, ragents and microfludic chips. The microfludic design is making a mirco liquid path system become a consumable product possible and offer feasible and cost-competitive solutions for many designs, like Gene related machine, CAR-T innovations, to avoid system-level cross-contamination. Keyto Maicrofludic and consumable solutions have both standard products compatible with other brands and customized products for customer needs.

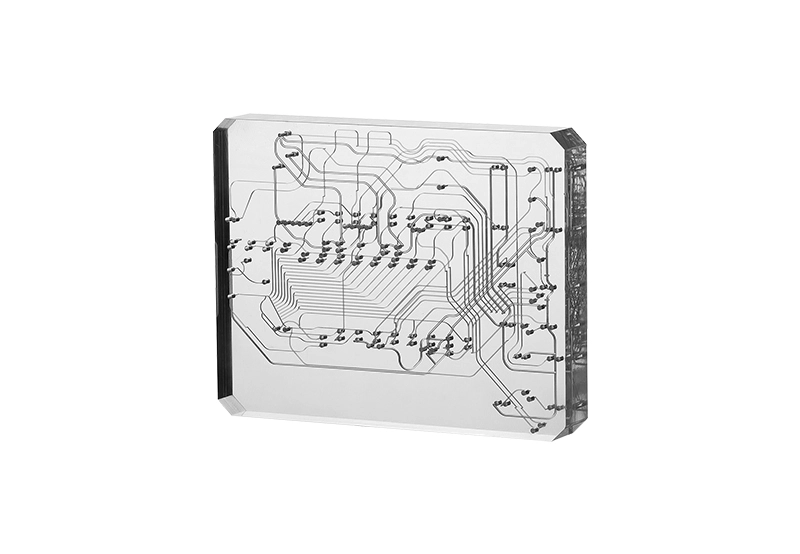

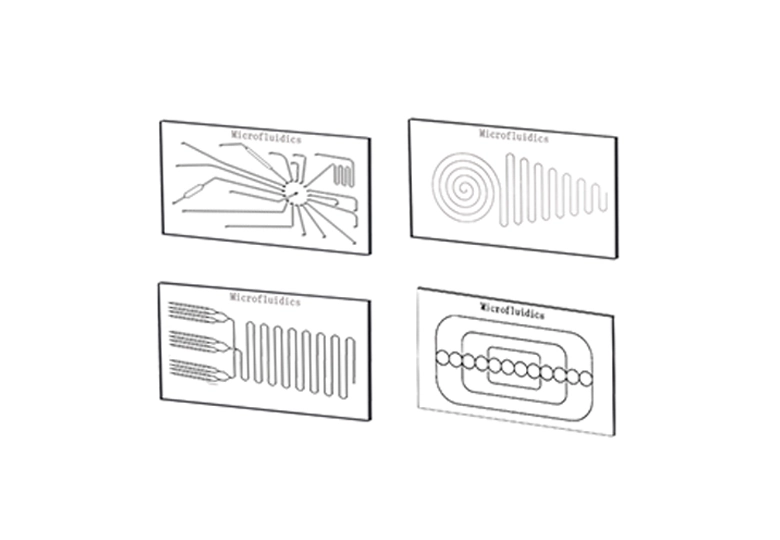

Microfluidics is the study of systems that can process small quantities of fluids by using tiny channels having dimensions at the microscale – typically tens to hundreds of micrometres. Although in the nascent stage, microfluidics is rapidly emerging as a breakthrough technology that finds applications in diverse fields ranging from biology, IVD and chemistry to information technology and optics.

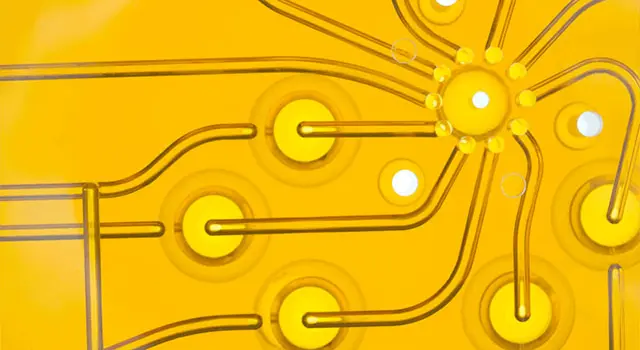

And The fluid path is formed by microfluidic channels to control the liquid to achieve various functions, often used in various instruments such as molecular diagnostics, gene sequencing, and so on.

Compared to conventional assays, microfluidic chips have more stringent requirements for detection. For example, it requires high sensitivity, fast response time, and a smaller size. So now optical and electrochemical detection is the most widely used technology for microfluidic.

Microfludic technology offers a compelete new solutions to achieve a small size for a fluid system since lots of tubes are replaced by fluidic path in-between plactic plates. With further exploring the technique, scientists and senior technicians are investigaing the method of integrating the regents into the microfludic manifolds to further reduce instruments flexibility and make it portable.

Microfludic manifolds and chips now becomes a critial component for life science and analytical instruments. The manifolds have to major restrains, one is design-a robust and simplified flow path is essential for further manufacturing, the other one is process development-to get a manifold into to stable and efficient prodction to guarante the quality assurance.

Both the design and development improvement will make the polymer manifolds becomes affordable consumable which will significantly reduce cross-containmination and improve the test flexibility and efficiency.