+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

Breakthrough from 0 to 1

--The First High Precision Proportional Valve for Ventilators in China at Keyto

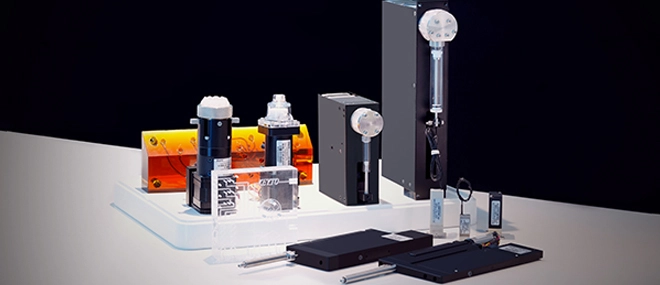

On June 12, 2020, China's first high-precision proportional valve for ventilators was successfully developed at Shenzhen Keyto Fluid Control Co., Ltd. and put into small series production simultaneously, intending to apply for a patent worldwide.

China is the world's largest producer of ventilators, with a total of 22 ventilator manufacturers, of which eight have passed the mandatory certification of the EU to be qualified to export to Europe. However, the production capacity of these eight manufacturers alone accounts for 20% of the world's share of ventilators. But all ''proportional valves'' must be imported from Europe and the United States.

These critical components meet their local demands first, and export in small batches will be a secondary consideration. However, due to various reasons, the already scarce resources of the core components can not meet the market supply, becoming hard to get.

''Rising to the Challenge Instead of Escaping/Doing Nothing''

Shenzhen Keyto Fluid Control Co., Ltd. specializes in components and sub-system solutions for precision fluid control, including solenoid valves, diaphragm pumps, piston pumps, fluid control modules, bonded manifolds, and precision machined components.

Keyto, with its highly reliable product design and refined quality control, mature application in high-end microfluidic control and analysis occasions, has become a leading domestic brand in precision fluid control, especially in the field of IVD medical equipment. Keyto counts as the top choice for these companies. But for the core components of respirators - ''proportional valve'' related fields have not been involved, which is unfamiliar territory for Keyto.

Should we get involved?

How to get involved?

These questions have become the hurdle in front of Zhang Cheng, the founder of Keyto Fluid. However, with a keen sense of the market as well as the sense of responsibility and mission to ensure the supply of medical equipment. Mr. Zhang silently clenched his fist and decided inwardly to cross the hurdle he was facing.

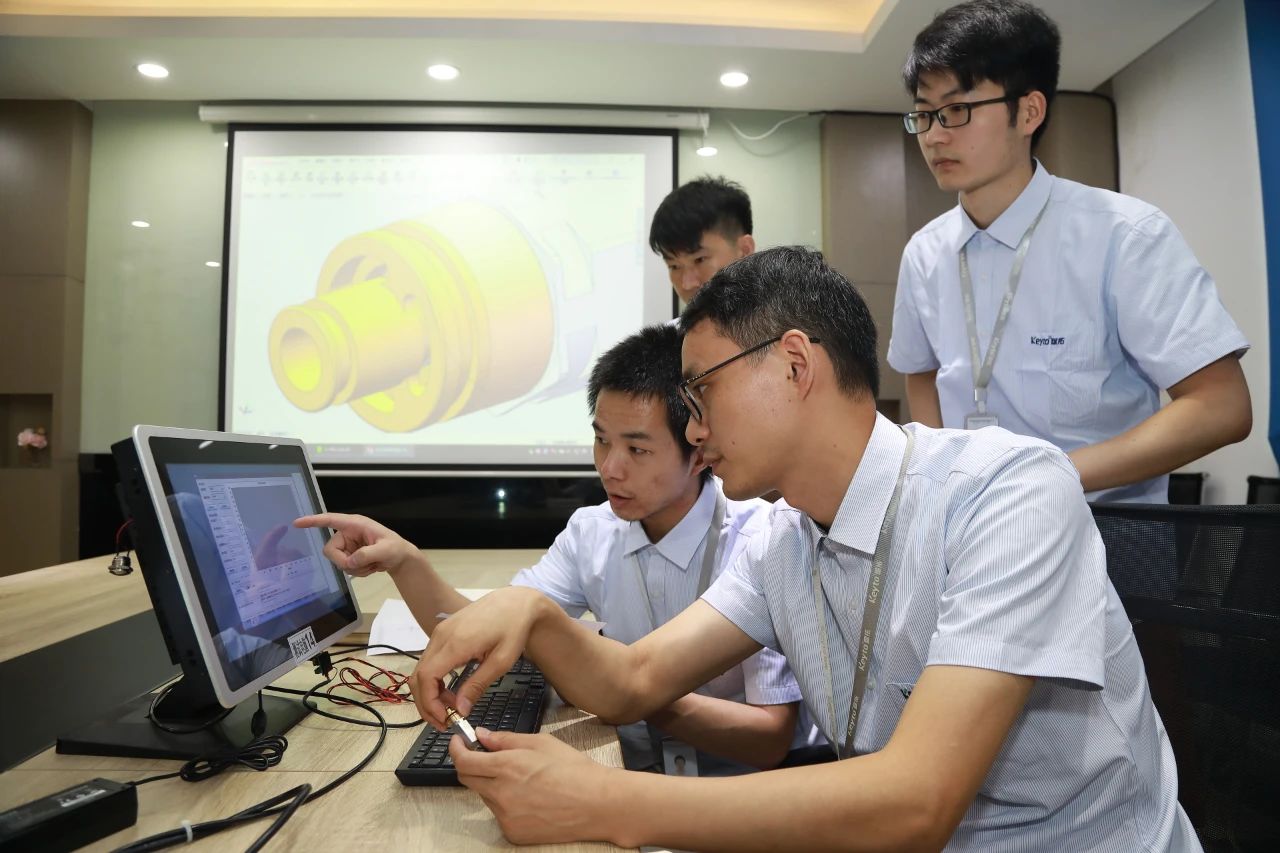

Mr. Zhang is discussing the structure of the proportional valve with colleagues in the R&D Department.

On January 23, 2020, Yang Gonghuan, former deputy director of the Chinese Center for Disease Control and Prevention, predicted that February might be the outbreak's peak.

Shortly after the Chinese New Year holiday, Mr. Zhang informed the company to make early arrangements to resume work and production. With Wuhan being locked down, began rampaging around some cities across the country. At the same time, medical supplies are extremely tight, and a large number of manufacturers of medical testing equipment would undoubtedly be in urgent need of precision fluid control components. It's time for Keyto to contribute to the fight against the epidemic!

On the one hand, under the call of Mr. Zhang, Keyto staff worked overtime and against the clock for more than one month to ensure the production and supply of high-end liquid handling components for Chinese medical equipment manufacturers. On the other hand, many ventilator manufacturers in China cannot complete the delivery of the whole machine due to the lack of the core component - the miniature proportional valves.

Therefore, much clinical sourcing booked hotels nearby the factories, waiting for the finished products in order to win over the supply of ventilators. They were prepared with sufficient cash to pick up the goods. However, the chances of getting a supply of ventilators were still extremely slim.

Within a month, the global ad changed suddenly. In April, Mr. Zhang gathered the R&D team to analyze the current international situation carefully and then announced the launch of the ''Proportional Valve'' project at the same time. It is a field (proportional valve) into which Keyto has never ventured before, but the situation no longer allows for hesitation.

''Fellows, I am the project leader and will work with you all to overcome the obstacles! So let's rise to the challenge instead of doing nothing! After May 1, we must put the product into small-scale production. Then, all the departments, channels, and projects should make way for this proportional valve project.'' Mr. Zhang said encouragingly at the project meeting.

''When you scale up the difficulties slightly, the chances of success are even slimmer.''

The ventilator is one of the three major routine clinical life-saving devices, providing respiratory support or recovery therapy for patients with respiratory failure or respiratory insufficiency. As the last life-support medical device for critically ill patients with lack of supply, it has become a mandatory purchase for designated treatment hospitals. Reliability of quality, longevity of operation, and failure-free rates are the only criteria for ventilator purchasing.

Keyto is all about transforming industrial knowledge and understanding of the market into customized fluid control solutions for our customers. ''Creating the most benefits and value for customers'' has become Keyto's motto.

Xiao, general manager of the R&D system at Keyto, is discussing the issue of proportional valve decurved with the team.

At the technical seminar, it was agreed that there are three widely used exhalation valves: flapper exhalation valves, pilot-operated exhalation valves, and solenoid proportional valves. The flapper exhalation valve is a duckbill-shaped one-way flapper made of lightweight material. In comparison, the pilot-operated exhalation valve uses a pre-set pressure to regulate the opening and closing of the valve.

As for the solenoid proportional valve, the opening and closing of the valve plate are controlled by electromagnetic force generated by an energized wire in a magnetic field. As a result, it has very little resistance and performs better in accuracy, power consumption, response time, flow rate, and high reliability than the other two types of valve.

However, manufacturing technology is highly demanding and has long been occupied by European and American companies. Despite all this, Mr. Zhang resolutely decided to develop a solenoid proportional valve after a discussion with R&D technicians.

More importantly, the decision should be made to innovate and eliminate plagiarism. Everyone knew the team's challenges during the R&D process were enormous and unimaginable. Mr. Zhang emphasized: ''When you scale up the difficulties slightly, the chances of success are even slimmer. So it would be best if we magnified the possibility of success infinitely, and then difficulties will be nothing to fear''.

Mr. Zhang is discussing the proportional valve technology with Xiao.

Xiao, general manager of R&D systems, is the inventor of 25 patents. Under his leadership, he organized a large group of scientific researchers with a wide range of knowledge in the company. The group encountered difficulties at the beginning of the R&D.

Proportional control is a closed-loop control system where the change in the output variable is proportional (positive or negative) to the difference in the feedback signal. Proportional flow control means a variable current (input variable) is applied to the gas control system. In contrast, the gas pressure and temperature in the gas circuit remain constant, thus changing the aperture of the gas circuit so that the flow of gas (output variable) is proportional to the change in current (input variable). So far, proportional flow control technology is one of the most challenging fields of fluid mechanics. Technical difficulties still cannot be overcome with the existing technology.

The proportional Solenoid Valve is the executive element in achieving proportional flow control. Its working principle: the control computer regulates the opening size of the solenoid valve by supplying different currents to the solenoid valve according to the various release requirements of the gas, thus controlling the airflow through the solenoid valve. The proportional solenoid valves on ventilators are used as inspiratory valves and play an essential role in air and oxygen mixing and precise gas release. Ventilators used in hospital clinics and medical emergencies require a master control valve set capable of outputting up to 180L/min flow, with a concise response cycle (typically less than 10ms) and accurate proportional distribution and mixing functions. For a technologically advanced ventilator, these prerequisites, combined with ''intelligent'' control algorithms, are necessary to provide adequate ventilation support and excellent comfort to the patient.

However, at this point, a problem stranded the team. The R&D department could not solve the 180L/min flow rate problem no matter what, and failure to meet this standard would mean that the development of the proportional valve would fail. Mr. Zhang, also an inventor with 20 patents, would still be involved in the actual development of the project in addition to handling a lot of company business.

After reviewing a great deal of domestic and international information, he suddenly realized the real problem. The direction of R&D had gone wrong because everyone was focused on optimizing the product parameters without taking into account the one-to-one correspondence with the top product parameters in actual use. Having found the core of the problem, the team decisively made a significant adjustment in the direction of R&D. After Mr. Zhang's analysis, the members were enlightened and suddenly felt refreshed. Everyone was as excited as if they had discovered a new continent.

Mr. Zhang was involved in discussions with the R&D department on the core issues of proportional valves.

Zhang Li, the general manager of the supply chain system, is also dedicated to his work for the whole R&D supply. He coordinates dozens of suppliers simultaneously and visits almost all of them, including the processing and materials departments. He is also involved in all matters relating to this project. He said, ''There are different options for the type of materials, processes and dimensions, if we combine these different options together, the number of product types would be a giant number.''

Without the strong support of the supply chain, this project would not have been possible in a short time. The critical is to find the most suitable material among the lots available, optimize it for the various versions, breakthrough processes, and bottlenecks, and even develop simultaneously in urgent cases. To get the scheme from the R&D department, the supplier waited until midnight. They started processing the material overnight as soon as they reached the project.

By 8 o'clock the following day, They had already delivered the processed materials to the R&D department. The supply chain system organically integrated all people, organizations, and materials within the system as a unity and everyone reached an extremely high level of awareness. In the course of the project, the whole company presented an exceptionally wonderful atmosphere, and everyone was united with a high-spirited attitude to win honors for the company. With the cooperation of each link, including R&D, designing, processing, prototyping, materials, and testing, after more than 30 days and nights of sleepless over time, they finally produced the prototype on May 8!

After a series of rigorous tests such as unconventional pressurization, aging, and vibration resistance, the prototype has reached the design index. Mr. Zhang immediately arranged for relevant customers to take products for actual testing and collect relevant data. After one month of repeated modification and adjustment, all product indexes had fully met the standards of their foreign counterparts. The product is now being supplied to the domestic market and exported abroad.

Breakthrough from 0 to 1

With ten years of technology accumulation, the dedication of engineers, and the strong support of the company's senior managers, Keyto has not only achieved a breakthrough from 0 to 1 but also made the product into an industry leader that it was not familiar with in the past.

Keyto previously produced conventional valves with states of opening and closing only. Proportional valves can hover in any position through an electrical control system, and the flow control is not simply a matter of opening and closing. In terms of difficulty, proportional valves and conventional solenoid valves are not at the same level. Nevertheless, Keyto is already a pioneer in traditional valves.

The successful development of the proportional valve has allowed Keyto to stand at the top of the respirator component field again. Breakthrough from 0 to 1 is the concept of nothing to something. Keyto has enabled China to achieve a breakthrough in the field of proportional valves from scratch. More importantly, the Keyto proportional valve has reached a superior level.

''Our goal is not to be the second in the world. Instead, we should improve the manufacturing level from 'Made in China' to Intelligent Manufacturing in China and make the Chinese 'Proportional Valve' a symbol of the global medical device industry. The Proportional Valve's successful development is a full consolidation of our position in the fluid control industry, a highlight in company growth, and a significant gift for Keyto's 10th anniversary.'' Zhang Cheng, the founder of Keyto, said proudly.

Keyto's philosophy is ''Fight For Human Health And Safety, Environment Beauty And Comfort.'' The successful development of this high-precision proportional valve is the best interpretation of Keyto's philosophy. Keyto people will be the early risers who stand at the top of the industry and strive for the motherland's prosperity and the company's dream.

Copyright by Keyto International Marketing Dept.

Contact: info@keyto.com

Aug 4, 2022