+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

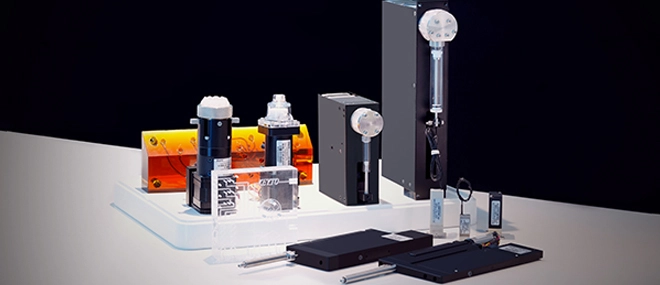

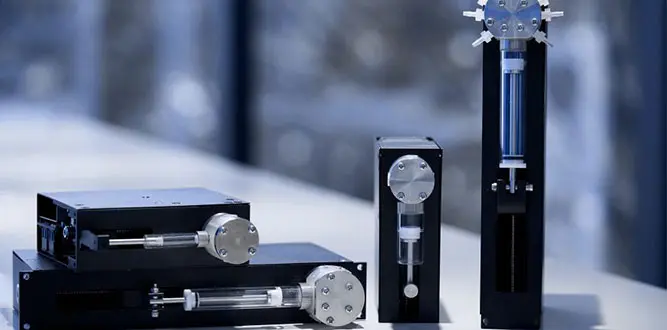

Liquid handling components become a very critical part of lab process standardization and automation. To better serve and support Keyto global customers, Keyto developed and innovated Superb Air Displacement Pipetting product line SADP 16, 18, 20, 28, Programmable Syringe Pump, Metering Pump, Rotary Shear Valve and Piston Syringe Pump to achieve good accuracy and precision. By applying Keyto liquid handling solutions, customer design will have less piece-to-piece variation then improve product performance and reliability. In general, Keyto liquid handling components and be applied in various industries' lab process optimization, like ELISA, time-resolved fluorescence, nucleic acid preparation, PCR setup, next-generation sequencing for genomic research, TLC spotting, SPE, liquid-liquid extraction, drug discovery, etc...

The acid, alkaline, viscosity of reagent.

The volume, material, structure of liquid handling pumps.

The type of motor and lead screw.

Pharmaceutical industry requires millions of repeatable tests for the development and validation to make sure the newly developed products are effective and meeting the regulation. In the whole development process the automated liquid handling instruments are the basic and best infrastructure to eliminate human falts and improve the validation tests robustness. With more and more automated pipette machines come to the markets, automated liquid handling platforms with integrated automated pipette machines becomes good options of the pharmaceutical industry.

When selecting a trusted supplier for your liquid handling components, Keyto should be at the top of your list. Keyto stands out as a preferred choice due to their extensive range of high-quality products and exceptional service.

Keyto offers a wide selection of liquid handling components, including liquid handling pipettes, automated pipettor components, and liquid handling robot syringe pumps. Their comprehensive product range caters to the diverse needs of laboratory researchers and pharmaceutical companies, ensuring all your fluid handling requirements are met.

Keyto is committed to delivering superior quality components. Their products are manufactured using advanced technologies and undergo rigorous quality control processes to guarantee durability, accuracy, and consistency.

Keyto is continuously driving innovation in liquid handling components. They invest in research and development to introduce new technologies and enhance their product offerings. By choosing Keyto as your supplier, you gain access to the latest advancements in liquid handling, empowering you to improve the efficiency and accuracy of your fluid handling processes.

In summary, Keyto is the ideal supplier for your liquid handling components due to their extensive product range, superior quality, exceptional customer service, and commitment to innovation. Choose Keyto to access top-quality liquid handling pipettes, automated pipettor components, and liquid handling robot syringe pumps.

Laboratory liquid handling plays a vital role in scientific research and various industries. Key components for this process include liquid handling pipettes, automated pipettor components, and liquid handling robot syringe pumps. These tools enable precise and accurate measurement, transfer, and dispensing of liquids in a controlled manner. Liquid handling pipettes allow manual handling, while automated pipettor components and liquid handling robot syringe pumps offer automation options for higher throughput and enhanced efficiency. These components are essential for achieving reliable and reproducible results in laboratory experiments, drug discovery, diagnostics, and various other applications.

Laboratory liquid handling is a critical process in scientific research and industrial applications. Key components include liquid handling pipettes, OEM liquid handling components, and liquid handling robot syringe pumps. Liquid handling pipettes allow precise measurement and transfer of liquids. OEM liquid handling components provide customizable solutions for specific requirements. Liquid handling robot syringe pumps offer automated fluid dispensing for increased efficiency and accuracy. Together, these components ensure reliable and controlled liquid handling, essential for achieving accurate results in various laboratory procedures and applications.

With the sample size increase in the laboratory, manual liquid transfer quickly becomes a bottleneck, requiring a long time and high concentration. Therefore,automated liquid handling stations are becoming increasingly attractive: automated liquid handling workstations can be placed between manual pipettes and complex robots.

Liquids are everywhere in the laboratory. Many analytical methods require liquid samples, and synthesis is usually carried out in the liquid phase, even in sample preparation. Therefore, treating liquid substances is the daily work of laboratory staff, and a pipette is an important tool.

Plate reformatting is one essential part in laboratory. It consists of transferring samples or compounds from one source microplate format to a destination plate with a different format. Therefore with the liquid handler automation, Platform reforming is also required to be automated and more compliant. There will be a whole solution of move pipette and plate.

Keyto liquid handling components and automated liquid handling systems contains an Air Displacement Pipettor, which can perfectly solve the problem of large sample size and is super suitable for lab auto workshops. In addition, we provide different OEM procedures for each terminal equipment customer to choose from.

Yes, OEM liquid handling pump choices are designed to support a wide range of intended applications. OEM liquid handling components are known for their flexibility and versatility, allowing for customization to meet specific requirements. These pumps are engineered to deliver precise liquid handling, ensuring accuracy and reproducibility in various laboratory applications. Whether it's sample preparation, assay development, or liquid transfer, OEM liquid handling pumps offer the necessary capabilities to achieve precise and reliable results. The use of precision liquid handling components in OEM pumps enables controlled and accurate dispensing, making them suitable for a diverse range of applications in industries such as biotechnology, pharmaceuticals, diagnostics, and research.

Yes, the available OEM components for liquid handling are typically scalable. OEM manufacturers understand that the needs of different applications may vary in terms of volume and throughput. Hence, they offer scalable solutions that can be easily adapted to accommodate different scales of operation. Whether it's increasing the number of channels, expanding the capacity, or integrating with automation systems, OEM liquid handling components can be scaled up or down to meet the changing demands of the application. This scalability makes them suitable for both small-scale research laboratories and large-scale industrial settings.

The four levels of automated process are:

1) Manual: In this level, all tasks are performed manually by human operators with no automation involved.

2) Partial Automation: Some tasks are automated, while others are still performed manually by human operators.

3) Semi-Automation: Most of the tasks are automated, with minimal manual intervention required.

4) Full Automation: All tasks are fully automated, with no need for human intervention except for programming and monitoring the automated system.

These levels represent the progression from manual operation to complete automation, with increasing degrees of efficiency, accuracy, and reduced human involvement as we move up the levels.