+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

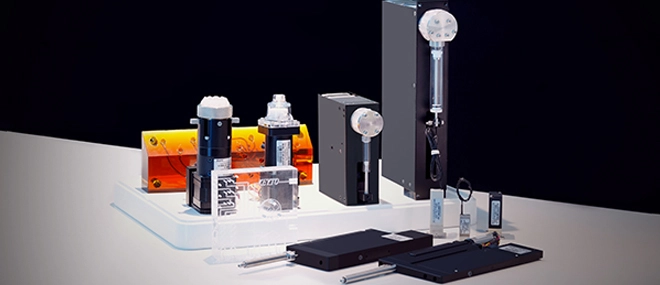

Keyto is a leading manufacturer of micro solenoid valves. We handle everything in-house, from design and development to production and sales. With over decades of experience, we've perfected our craft and provide valves for a wide range of applications. Our miniature and micro solenoid valves include:

Valve Structures: rocker isolated, direct-acting isolated, and plunger isolated.

Diameters: 0.8mm, 1mm, 1.5mm, 1.6mm, 2mm, 2.5mm, 3mm, 4mm, 4.5mm.

Fluid Wetted Materials: EPDM, FKM, ETP, FFKM, POM, PPS, PEEK, PVDF, PTFE.

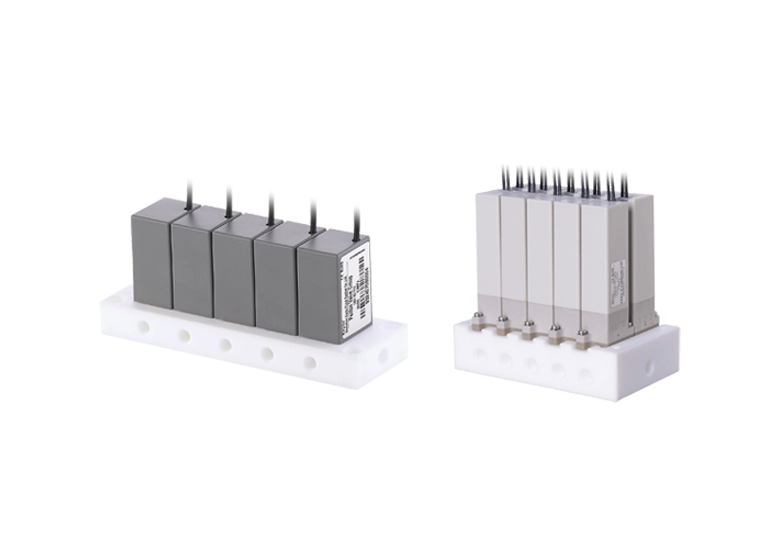

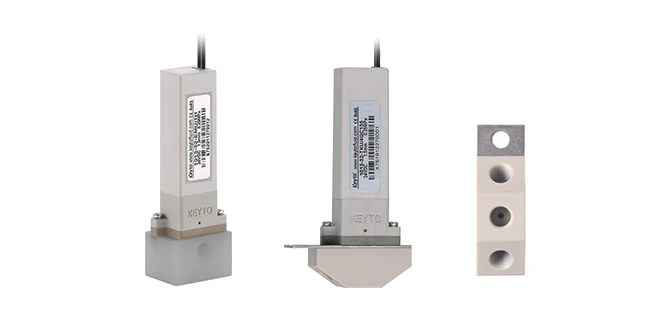

Installation Types: tubing, base mounted (manifold integration), threaded (1/4-28UNF, M6, G1/8).

Driven from Cooper wire coil then the applied temperature and voltage are critical.

Keyto solenoids can be compatible with both gas and liquid, therefore to provide the interface between liquid and gas will be very important for Keyto team to make recommendations.

Keyto have both on/off and proportional solutions for customer application in life science, In Vitro Diagnostic and Industry field.

Keyto micro solenoid valve is divided into three categories from the principle: direct-acting, rocker type, and diaphragm type. And from the difference in valve structure and material and the direction of the difference is divided into six sub-categories: direct-acting diaphragm structure, rocker type structure, and grouping diaphragm type structure. The application can be divided into a standard solenoid valve, a high-temperature and high-pressure solenoid valve, and a pinch valve.

Principle: When energized, the solenoid valve coil generates electromagnetic force to lift the closure from the valve seat, and the valve opens; when disconnected, the electromagnetic energy disappears, and the spring force presses the closure on the valve seat, and the valve closes.

Valve is a control component in the fluid transfer system, with processes such as shutoff, regulation, infusion, backflow prevention, pressure stabilization, diversion, or overflow pressure relief. And the valve does not pump power source can only be furnished.

The pump is the power source. The valve is the control element. The power source generated by the pump needs to be controlled with the valve to produce the system pressure, flow, and direction of motion.