+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

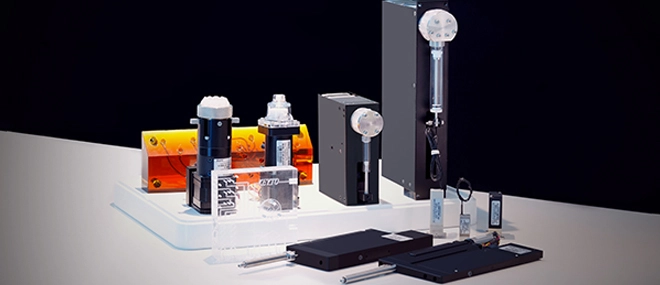

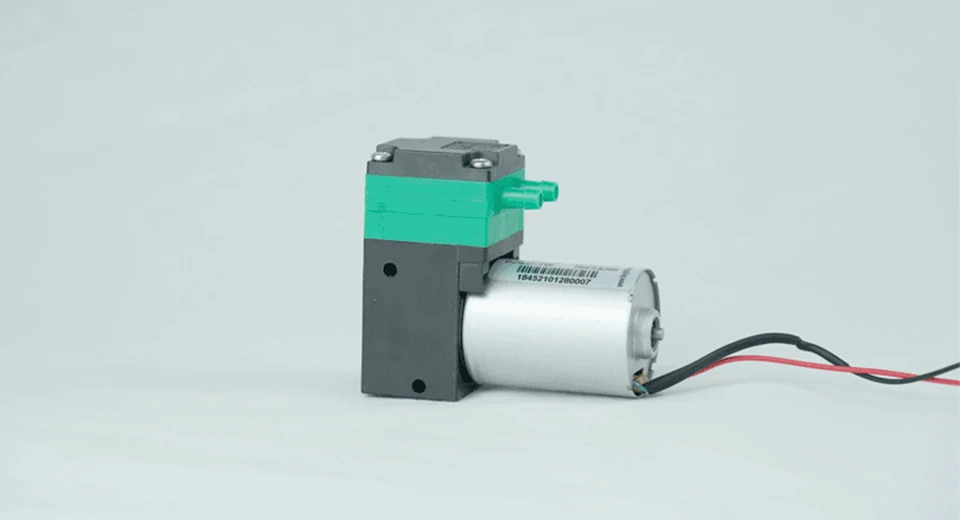

Keyto miniature diaphragm pumps offer oil-free operation, ideal for transferring contaminated air, liquids, or air with liquid particles. Available in single or dual head configurations with brushed or brushless DC motors. With an excellent cost-to-lifetime ratio, Keyto’s diaphragm pumps are a trusted choice for applications demanding durability and consistent performance over time. Find the perfect pump for your needs today!

Working Principle of Miniature Diaphragm Pumps

Keyto's miniature diaphragm pumps, also known as mini wash pumps, diaphragm mini pumps, micro suction pumps, mini diaphragm pump, membrane pumps, and diaphragm pumps for liquid and gas, operate through a micro DC motor-driven diaphragm mechanism. The motor, either brushed or brushless, drives the diaphragm using an eccentric wheel, creating a reciprocating motion. As the diaphragm moves, it alters the volume within the pump chamber, allowing air or liquid to be drawn in through an inlet valve and expelled through an outlet valve. These one-way valves ensure proper flow direction and efficient fluid transfer. The oil-free design guarantees clean, contamination-free operation, and the pump’s compact size makes it ideal for integration into small systems.

When it comes to selecting the right mini diaphragm pump, it's important to understand the different types available and their specific uses. There are two main types of mini diaphragm pumps: mini diaphragm liquid pumps and miniature diaphragm air pumps. In this selection guide, we will explore these types and their applications.

The first type is the mini diaphragm liquid pump, which is designed to handle various liquids. One popular example is the mini diaphragm water pump. These pumps are commonly used in applications where small volumes of water need to be pumped, such as in portable water systems or small irrigation setups. They are compact, reliable, and efficient, making them ideal for use in tight spaces or on-the-go.

On the other hand, miniature diaphragm air pumps are designed to handle air or gases. They are known for their compact size and ability to deliver consistent airflow. These pumps are commonly used in applications such as air sampling, gas analysis, or even pneumatic control systems. Miniature diaphragm air pumps are often chosen for their precise pressure control and quiet operation.

In the medical field, diaphragm pumps play a crucial role. Medical diaphragm pumps are specifically designed to handle fluids or gases in a safe and controlled manner. They are constructed with materials that meet medical standards and ensure the utmost reliability and safety. Medical diaphragm pumps are used in applications such as drug delivery, respiratory therapy devices, or laboratory equipment.

When selecting a mini diaphragm pump, it is important to consider factors such as the flow rate, pressure requirements, and the specific fluid or gas being pumped. Additionally, the compatibility of the pump with the intended application and environmental conditions should be taken into account.

In conclusion, mini diaphragm pumps come in two main types: mini diaphragm liquid pumps and miniature diaphragm air pumps. The choice of pump depends on the specific requirements of the application. Whether it is a miniature diaphragm water pump for small-scale water pumping, miniature diaphragm air pumps for precise airflow control, or medical diaphragm pumps for handling fluids in a safe and controlled manner, there are various options available to suit your needs.

The choice between brushed and brushless DC motors depends on your specific needs. Brushed motors are cost-effective and ideal for less demanding operations, while brushless motors offer longer life and better efficiency for high-performance applications.

Yes, Keyto's miniature diaphragm pumps are versatile and can handle both air and liquid, with specific models optimized for each medium.

Keyto precision liquid and gas pumps are made from durable, high-quality materials such as EPDM, FKM, PTFE diaphragms, and more, depending on the application's chemical compatibility and performance needs.

Yes, we offer a range of customization options to meet specific performance requirements, including different motor types, materials, and configurations to suit your unique fluid control needs.

The life expectancy varies based on the application and operational conditions, but our pumps are designed for extended service with minimal maintenance, ensuring a superior cost-to-lifetime ratio.