+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

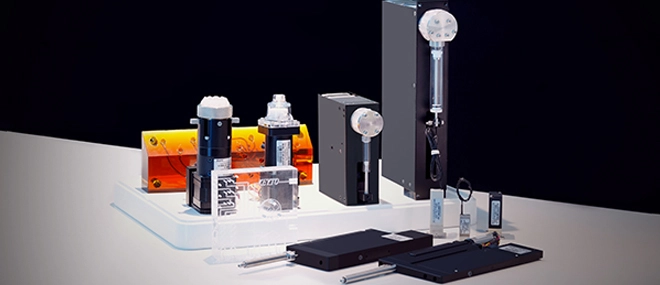

31XX series multi-channel rotary valve is a product independently developed by Keyto, the main function is to achieve multi-channel switching. This series of rotary valve has a variety of model selection. Moreover, this series of rotary valves can withstand different reagents under different working conditions, and the operating life can reach more than 1 million times.

Item | Specification | ||||

Number of channels | 6 Channels | 10 Channels | 12 Channels | 16 Channels | 24 Channels |

Contact liquid material | PCTFE, Sapphire, Ceramic | PEEK, Sapphire, Ceramic | |||

Initial position detection | Set to automatically detect the initial position after power on | ||||

Port to port volume | 27ul | 27ul | Upper: 25.5ul Lower: 24ul | Upper: 33.4ul Lower: 28.5ul | 4.6ul |

Runner diameter | 1.2mm | 1.2mm | 1.0mm | 1.0mm | 0.5mm |

Operating temperature | 0-50ºC | ||||

Operating humidity | ≤80% | ||||

Valve head flow temperature | 0-80ºC | ||||

Connection | 1/4-28 UNF, 10-30 UNF, 6-40 UNF | ||||

Replaceable parts | Can be replaceable valve head | ||||

Transposition performance | Multiple locations, random start | ||||

Optional driver board | No | ||||

Switching time | ≤2.5s/circle, 24-channel rotary valve ≤2s/circle | ||||

Maximum driving force/torque | 2.1N/M | ||||

Available communication protocols | RS232/RS485/CAN Bus | ||||

Communication rate | 9600dps | ||||

Device address setting | Serial port settings | ||||

Device parameter setting | Serial port settings | ||||

Overall dimensions | See 2.3.1 | ||||

Input power | DC24V±10% | ||||

Maximum power | 48W | ||||

Pressure | 6-16 channels: 0-0.7MPA 24 channels: 0-0.3MPa | ||||

Weight | 6-12 channels≈0.78kg 16-24 channels≈0.93kg | ||||

Note: Please kindly reach out to our sales team for design and specification final clarification and confirmation.

The rotary valve adopts sapphire spool, which can be applied to all kinds of corrosive liquids. The valve head is processed by PCTFE (polytrifluoroethylene), which is maintenance-free.

Spool rotor rotation depends on the planetary reducer motor as the power device.

Advanced zirconia ceramic processing technology, strict inspection procedures, unique sealing scheme, to ensure that the service life of the valve can reach more than 1 million times, without maintenance and care.

Contact with liquid medium parts of the material of good chemical resistance. Various materials can be selected to ensure the compatibility of chemical media.