+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

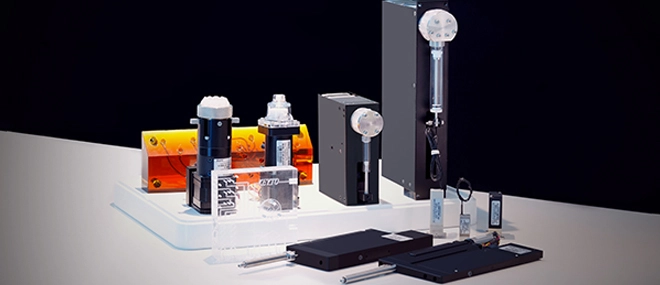

Valve&pump integrated is a product of combining precision piston pump and solenoid valve that is independently developed by Keyto, its mainly function is to achieve accurate quantitative aspiration and dispense of liquid. The piston pump has high accuracy and CV value, and its service life can reach more than 5 million times. It is a high performance, low cost, maintenance-free precision piston pump. Valve&pump integrated has been widely used in medical devices and laboratory analytical instruments.

Highly Customized: Valve Integrated Syringe Pumps can be customized with different applications, like different specification of flow control maps, different arrangement methods and mounting ports according to customers' requirement.

Here is one of the customized valve&pump integrated products: 50XX-P+1013 2-way Series.

50XX-P+1013 Series Integrated Module Specification

Maximum displacement (uL) | 100 | 250 | 500 | 1000 | 2500 | 5000 |

Plunger diameter(mm) | 3.17 | 5.01 | 7.08 | 10.01 | 15.84 | 22.39 |

volume per step(ul/step) | 0.05 | 0.125 | 0.25 | 0.5 | 1.25 | 2.5 |

Total travel distance(mm) | 12.7 | |||||

Lead(mm) | 1.27 | |||||

Travel distance per step(mm/step) | 0.00635 | |||||

Product life cycle note1 | 5 million | |||||

Coefficient of variation(CV)note2 | 1.5% | |||||

Accuracynote3 | 2% | |||||

Working pressure(MPa) | 0.3 | |||||

Port connection | 1/4-28 UNF or M6 | |||||

Mediumnote4 | Water, weak acid and base liquid, etc. | |||||

Note: Note 1: When the working medium is gas, pls contact us to determine the suitable P/N; Note 2: The nominal CV is measured at 2% of the total displacement; Note 3: The nominal accuracy is measured at 2% of the total displacement; Note 4: If other types of reagents are used, test verification is required. Please contact our technical staff. | ||||||

Operating Voltage (V) | 12V/24V±10% DC |

Withstand pressure(kPa) | -80kPa ~ +300kPa |

Orifice(mm) | 1.5 |

CV | 0.03 |

Response time(ms) | <30 |

Life cycle | 2 million |

Dead volume | 0 |

Power(W) | 24V:2.8W; 12V:3.2W |

Port connection | 1/4-28 UNF or M6 |

Medium | Water, weak acid and base liquid, etc. |

Note: Please kindly reach out to our sales team for design and specification final clarification and confirmation.

The nominal displacement is 100uL~5ml, and various models are available.

In the life cycle of the pump, with a very high and stable quantitative CV value. When testing with deionized water as a medium, the CV value is as follows:

Suction and dispense fluid percentage of total capacity | CV |

2% | <1.2% |

>10% | <0.5% |

Piston full travel distance: 12.7mm

Advanced processing technology of zirconia ceramic plunger,strict inspection procedures,unique sealing solutions,ensured that the service life of the pump can reach more than 5 million cycles, maintenance free.

The wetted material has good chemical resistance.

Optical detection at the end position, the sensor can determine whether the pump is in the initial position of the aspiration.