+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

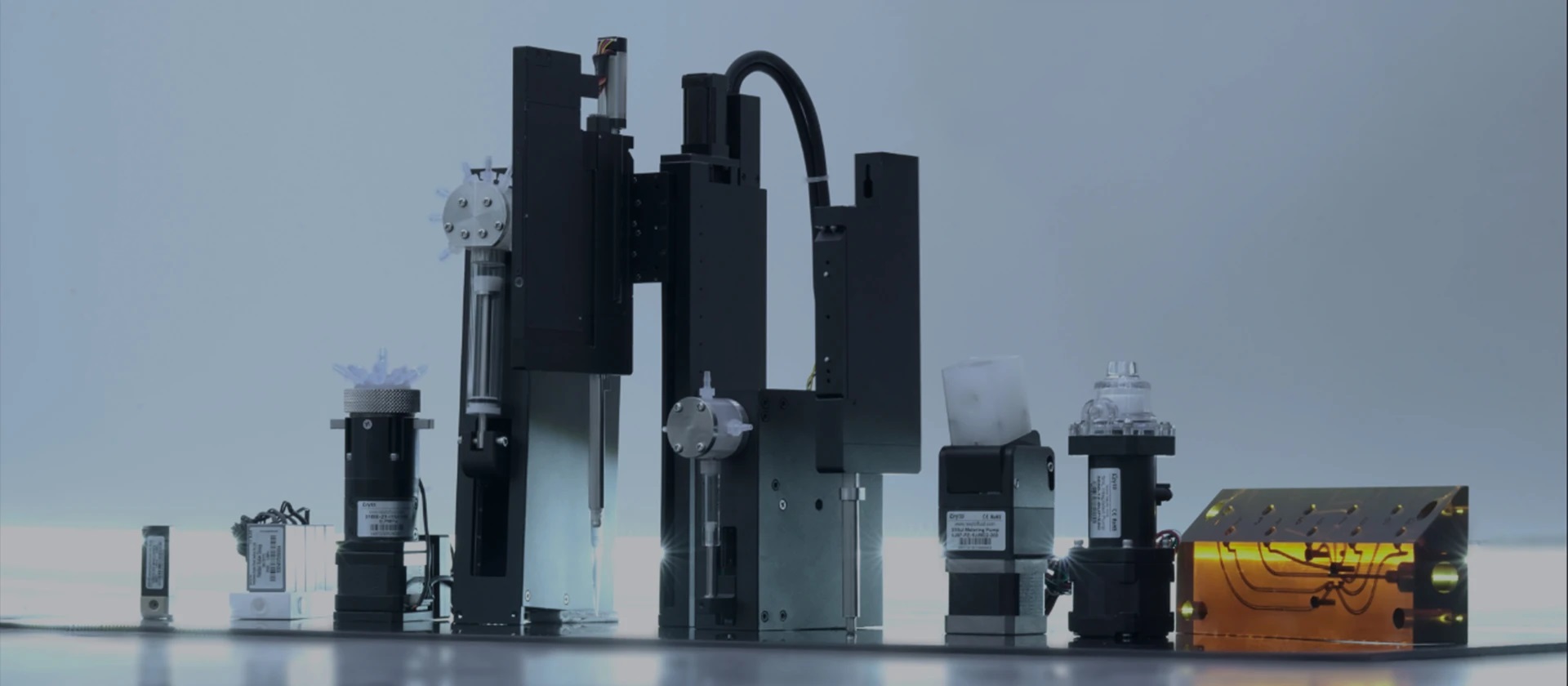

With the continuous progress of science and technology, the micro diaphragm pump, as a core component in the field of fluid transmission, is ushering in unprecedented development opportunities. From medical health to environmental monitoring, from precision manufacturing to scientific research experiments, micro diaphragm pumps continue to expand new application fields with their efficient, accurate and stable characteristics, and have spawned a series of innovative technologies.

In the medical and health field, micro diaphragm pumps are showing great application potential. For example, in portable medical devices, micro diaphragm pumps can achieve accurate liquid delivery, providing a stable and reliable power source for insulin injection pumps, infusion pumps and other equipment. In addition, micro diaphragm pumps are also widely used in critical medical equipment such as ventilators and hemodialysis machines to protect the life and health of patients.

In addition to their direct application in medical devices, micro diaphragm pumps of Keyto also play an important role in the field of drug development and biological experiments. By precisely controlling fluid flow and pressure, the micro diaphragm pump provides ideal experimental conditions for drug screening, cell culture and other experiments.

In the field of environmental monitoring, the application of micro diaphragm pumps can not be ignored. With the increasingly serious environmental problems, the real-time monitoring of environmental parameters such as air quality and water quality is increasingly urgent. With its efficient and stable performance, micro diaphragm pumps have become an indispensable part of environmental monitoring equipment.

In terms of technological innovation, the combination of micro diaphragm pumps with the Internet of Things, big data and other technologies has brought new changes to the field of environmental monitoring. Through real-time monitoring, data transmission and intelligent analysis, comprehensive control and early warning of environmental quality can be achieved, providing strong support for environmental protection and governance.

In the field of precision manufacturing, the application of micro diaphragm pumps has also made significant breakthroughs. With the transformation and upgrading of the manufacturing industry and the development of intelligence, the accuracy and stability of fluid transmission are increasingly required. The micro diaphragm pump has been widely used in the field of precision manufacturing because of its high precision, low noise and low vibration.

In terms of technological innovation, the combination of micro diaphragm pumps and precision manufacturing technology has brought higher production efficiency and product quality to the manufacturing industry. For example, in semiconductor manufacturing, precision instrument production and other fields, micro diaphragm pumps can achieve accurate liquid and gas transport, providing stable power support for the manufacturing process.

In the field of scientific research and experiments, the application of micro diaphragm pumps is also expanding. Whether it is chemical synthesis, material preparation or biological experiments, precise control of the fluid is required. Because of its high performance and reliability, micro diaphragm pump has been widely used in the field of scientific research and experiment.

In terms of technological innovation, the combination of micro diaphragm pump and experimental technology provides more possibilities for scientific research experiments. For example, in microfluidic chip experiments, the micro diaphragm pump can achieve accurate liquid transport and mixing, which provides a strong guarantee for the accuracy and reliability of the experimental results. In addition, with the continuous emergence of new materials and new technologies, the performance and reliability of micro diaphragm pumps will be further improved, providing more and better support for scientific research experiments.