+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

How to ensure that a qualified product remains intact and performs consistently from factory dispatch to customer delivery?

Ten years ago, KEYTO struggled with this issue. To simulate transportation, they arranged for an employee to drive a manual van, carrying dozens of company products through various small roads on the national highways of Shenzhen for 40-50 kilometers. The driver would intentionally hit every pothole to confirm if there was any risk of screws loosening due to vibration. Ensuring stable and reliable products has always been KEYTO's unwavering commitment.

In today's global trade era, logistics and transportation are integral to our daily work and life. However, the performance fluctuation of core components during long-distance transport cannot be ignored. KEYTO's mechanical laboratory now plays a crucial role in transportation assurance. The lab can effectively prevent and handle challenges such as vibration, drops, and jolts that products may encounter during transport or operation, earning KEYTO wide trust and praise from customers.

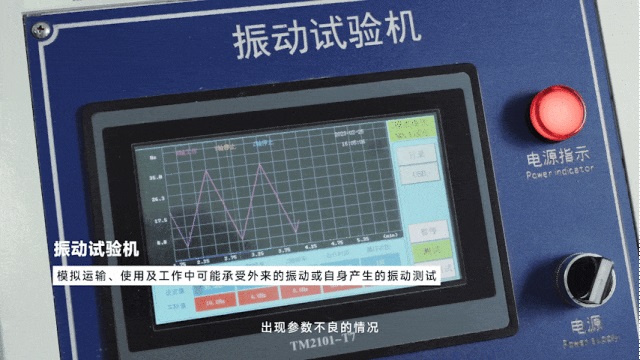

The bare machine vibration test is a critical validation method for KEYTO to comprehensively assess the vibration tolerance and reliability of its products. The entire process is autonomously completed using advanced vibration testing instruments. By precisely setting parameters such as the test frequency (5~35~5HZ cycle range), amplitude (0.35mm), number of frequency sweeps (15 times), and sweep rate (≤1 octave/min), it simulates the vibrations products may encounter during transport, usage, or in specific environmental conditions.

We adopt a bare-machine fixed test (replicating real operating conditions), performing low to high frequency and small to large amplitude reciprocal sweep tests to ensure the comprehensiveness and accuracy of the tests.

Low-frequency or small-amplitude tests simulate the vibration environment products may encounter during long-term transportation, storage, or usage, thereby evaluating the long-term stability and reliability of the products. High-frequency or large-amplitude tests can precisely detect the resonance frequency of products, simulating large amplitude vibrations that may occur at specific frequencies. This helps assess the structural strength, reliability of connections, and vibration resistance of internal components, ensuring that products remain intact and operational under extreme vibration conditions.

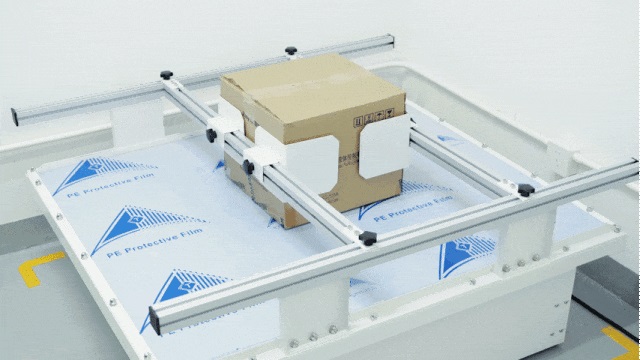

The simulated transport and packaging vibration test uses a simulated transport machine to accurately replicate the duration, vibration, and displacement of actual transportation. This helps verify whether the packaging integrity and protection measures can effectively safeguard the product, ensuring that its appearance, functionality, and performance meet factory standards. The company strictly adheres to the JTGBO1-2003 standard for first-class highways, simulating a driving distance of 200km at speeds between 30km/h to 40km/h, achieving equivalent tests through a high-precision simulated transport vibration platform.

During the process, quality personnel pack the products into boxes according to standards and place them on the simulated transport vibration platform. To ensure the accuracy of the tests, we adjust the fixed clamps to maintain a distance of about 5mm from the packaged surface and ensure a test duration of ≥7 hours.

It is worth noting that the vibration frequency of the platform produces varying intensities of vibration on the test pieces, helping to directly observe the true endurance capacity of the samples.

Continuous tests for ≥7 hours can simulate the stress impact of sustained vibrations during long-distance transportation, observing the overall performance of the test pieces in terms of appearance changes, internal structure changes, connection looseness, and functionality. This comprehensive assessment not only provides strong assurance for enhancing the stable operation of products but also is crucial evidence ensuring products meet industry standards and customer requirements.

The simulated packaging drop test is essential for ensuring the safety of packaged products in complex transportation environments. By using a drop test machine to simulate potential drop impacts during transport and handling, we assess the impact resistance of the packaging and the rationality of the packaging design, preventing damage to the products inside the box.

Additionally, the test data provides strong support for the quality control of packaging materials and products, helping us identify potential product defects and risks for timely improvements and optimizations.

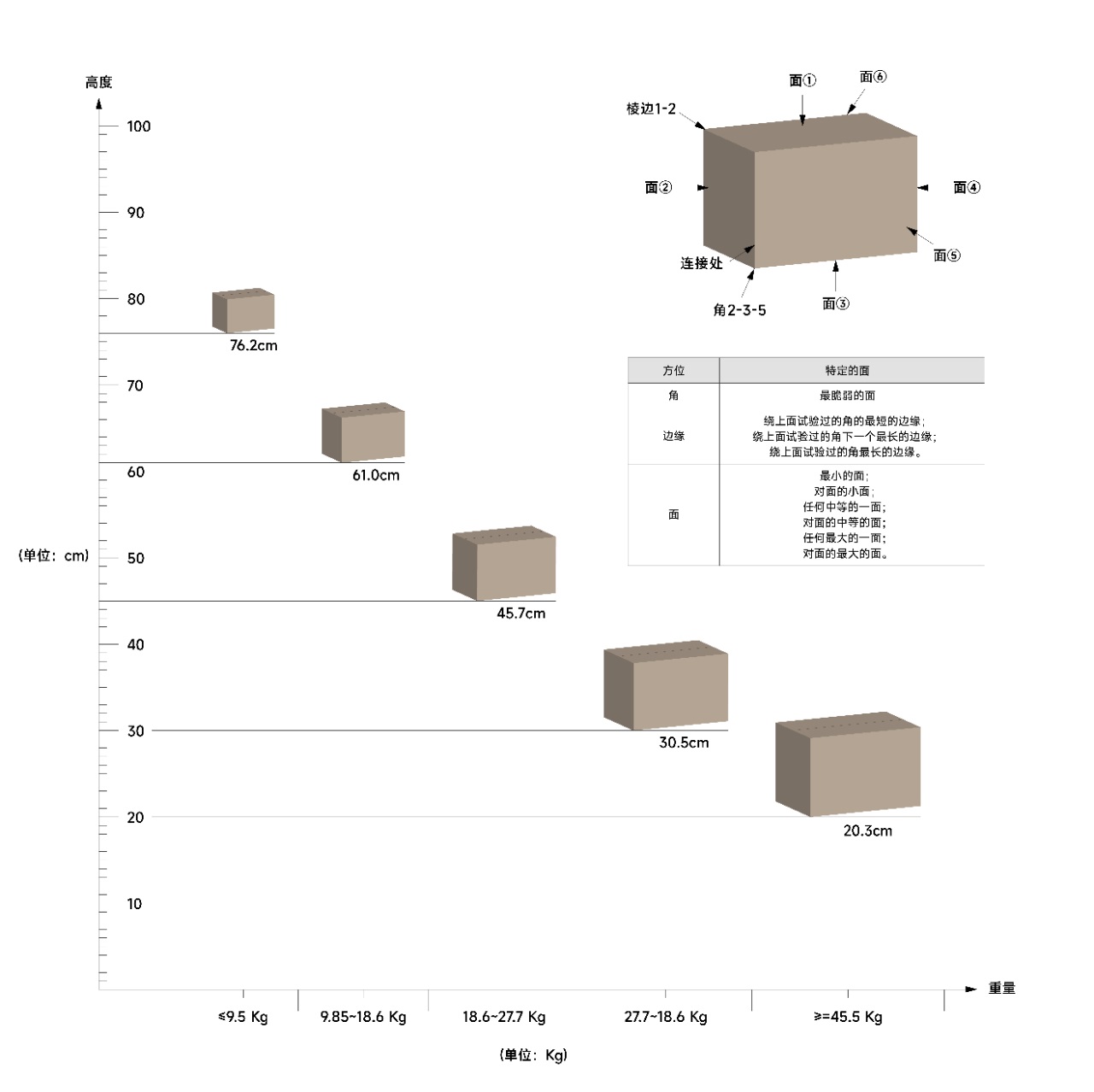

Based on the weight of the outer box, different drop heights are specified. We set up nearly ten drop tests for one corner, three edges, and six surfaces to comprehensively assess the drop resistance from all directions. The rigorous process effectively prevents potential damage during future shipping and transportation, providing solid assurance for the safe transport of products.

In recent years, KEYTO has continuously introduced international quality management concepts and advanced testing equipment. Combining the company's actual situation, it has continually improved and refined its quality management system. The company also focuses on close cooperation with suppliers and customers to jointly build an efficient, collaborative supply chain, ensuring stringent quality control from raw materials to finished products; in addition, KEYTO actively collaborates deeply with research institutions and universities to launch new products with independent intellectual property rights and market competitiveness.

In the future, KEYTO will continue to uphold the service tenet of "Quality First, Customer First," providing higher quality products and services to customers worldwide.