+86-755-29516669

- Gallery |

- VR View |

- OEM Service |

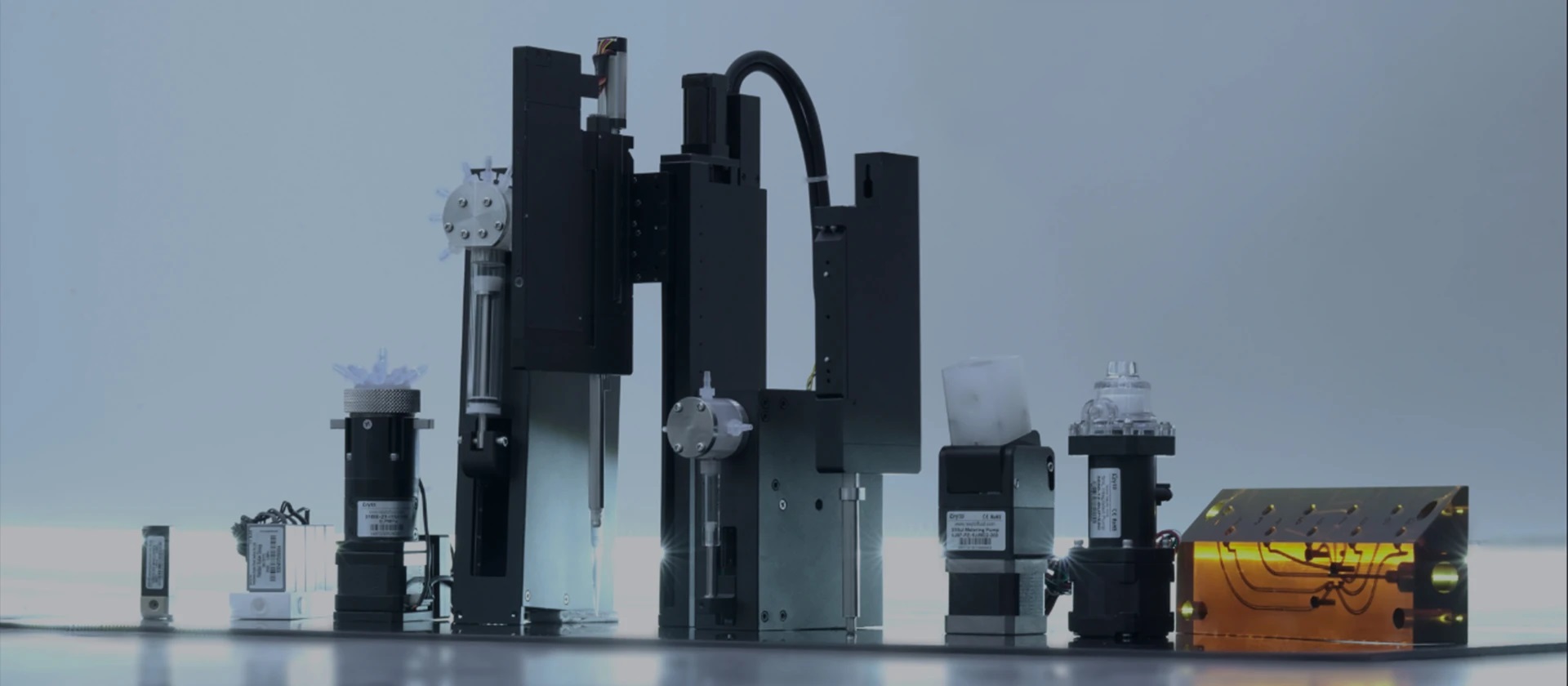

The outstanding feature of a metering pump is that it can keep a constant flow rate independent of discharge pressure. It can complete the functions of conveying, metering and adjustment at the same time, thus simplifying the production process. Using multiple metering pumps, several media can be input into the process flow in an accurate proportion for mixing. Because of its own prominence, it has been widely used in petrochemical, pharmaceutical, food and other industrial fields.

The worm is driven by the motor coupling, and the spindle and eccentric wheel rotate through the worm gear deceleration, and the eccentric wheel drives the sliding adjustment seat of the bow-shaped connecting rod to reciprocate. When the plunger moves to the back dead center, a vacuum is gradually formed in the pump cavity of the metering pump, and the suction valve opens to suck liquid; When the plunger moves to the front dead center, the suction valve is closed and the discharge valve is opened, and the liquid is discharged when the plunger moves further. In the reciprocating cycle of the pump, continuous pressure and quantitative discharge liquid are formed. When the metering pump is used for liquid transportation, the dosage range, pressure range, control mode, etc. can be selected, so that the transportation can be better completed and the use effect can be achieved.